Vibrating Screen

Vibrating Screen

Max Feeding Size:400 mm

Layer:2-4

Power:5.5-37kw

Capacity:60-800tph

Applied Materials: Limestone, Granite, Basalt, River Stone, Coal Gangue, Quartz, Diabase, Iron Ore, Copper Ore, Zinc Ore, Manganese Ore.

Features and technology advantages of Vibrating Screen

Introduction of Vibrating Screen

Circular vibrating screen is a new type of vibrating screen with circular vibration, multiple layers and high efficiency. Cylindrical vibrating screen adopts cylindrical eccentric shaft vibrator and eccentric block to adjust the amplitude. The material screen has long flowing line, many screening specifications, reliable structure, strong exciting force, high screening efficiency, low vibration noise, durability, convenient maintenance, safe use, etc. The vibrating screen is widely used for product classification in mining, building materials, transportation, energy, chemical and other industries.

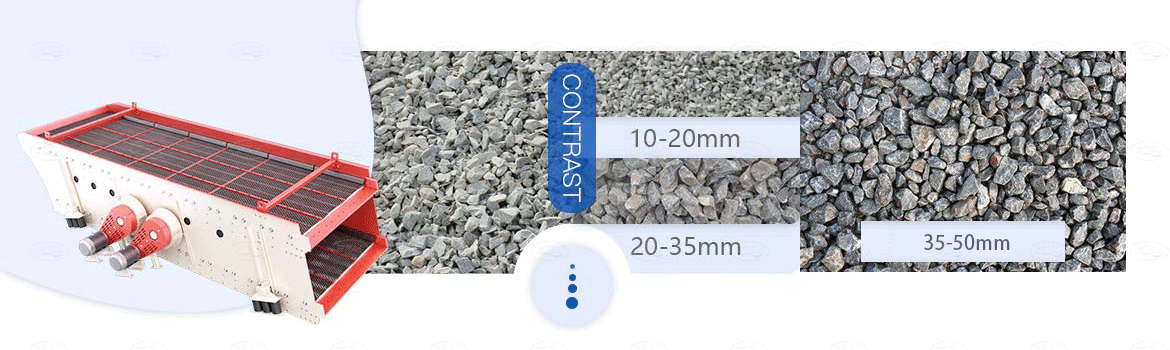

Screening: screening is to divide the granular and powder materials into different particle size groups. A single vibrating screen can be matched to 4 screens, which can conduct continuous separation of 2-5 particle sizes with narrow particle size range and control;

Screen out of impurities: during the high flow process of extreme performance screening machine, it can quickly remove large or small slurry residue particles. Vibrating screen can quickly remove all kinds of soluble solid materials in the slurry, and continuously screen the slag.

The movement of vibrating screen is round, and the series has a total of forty kinds of specifications. It can be used for the classification of materials in coal, mineral processing, building materials, electric power and chemical industry.

Advantage of Vibrating Screen

1. Sieving high frequency, small amplitude, high efficiency.

2. The moisture content of the material requirements low.

3. High efficiency, large capacity.

4. With eccentric block as exciting force, strong exciting force.

Working principle of Vibrating Screen

The circular vibrating screen is driven by the inertial vibrator with eccentric block fixed in the middle to make the screen box vibrate, so that the materials can be sieved through the screen mesh layer by layer.

Product Data

Technical Data of Vibrating Screen:

Model

Screen size (mm)

Screen layer

Sieve size (mm)

Maximum feed size (mm)

Capacity(Vh)

Power(Kw)

Vibration frequency(r/mln)

Double amplitude (mm)

2YK1237

3700*1200

2

3-80

100

10-80

11

750-950

6-9

3YK1237

3700*1200

3

3-80

100

10-80

11

750-950

6-9

2YK1548

4800*1500

2

3-80

100

30-200

11

750-950

6-9

3YK1548

4800*1500

3

3-80

100

30-200

15

750-950

6-9

4YK1548

4800*1500

4

3-80

100

30-200

15

750-950

6-9

2YK1848

4800*1800

2

3-80

100

50-250

18.5

750-950

6-9

3YK1848

4800*1800

3

3-80

100

50-250

18.5

750-950

6-9

2YK1860

6000*1800

2

3-80

100

60-300

18.5

750-950

6-9

3YK1860

6000*1800

3

3-80

100

60-300

22

750-950

6-9

4YK1860

6000*1800

4

3-80

100

60-300

30

750-950

6-9

2YK2160

6000*2100

2

3-80

100

80-400

22

750-950

6-9

3YK2160

6000*2100

3

3-80

100

80-400

30

750-950

6-9

4YK2160

6000*2100

4

3-80

100

80-400

30

750-950

6-9

2YK2460

6000*2400

2

3-80

200

100-500

30

750-950

6-9

3YK2460

6000*2400

3

3-80

200

100-500

37

750-950

6-9

4YK2460

6000*2400

4

3-80

200

100-500

37

750-950

6-9

2YK2475

7500*2400

2

3-80

200

100-500

30

750-950

6-9

3YK2475

7500*2400

3

3-80

200

100-500

37

750-950

6-9

4YK2475

7500*2400

4

3-80

200

100-500

37

750-950

6-9

2YK2870

7000*2800

2

3-80

200

100-700

2×22

750-950

6-9

3YK2870

7000*2800

3

3-80

200

100-700

2x30

650-850

6-9

4YK2870

7000*2800

4

3-80

200

100-700

2x30

650-850

6-9

2YK3072

7200*3000

2

3-80

200

150-800

2x30

650-850

6-9

3YK3072

7200*3000

3

3-80

200

150-800

2x30

650-850

6-9

2YK3272

7200*3200

2

3-80

200

150-800

2x30

650-850

6-9

3YK3272

7200*3200

3

3-80

200

150-800

2x30

650-850

6-9