Double Roller Crusher

Double Roller Crusher

Max Feeding Size:150(mm)

Discharging Size:2-50(mm)

Power:11-180(kw)

Capacity:10-150(t/h)

Features and technology advantages of Double Roller Crusher

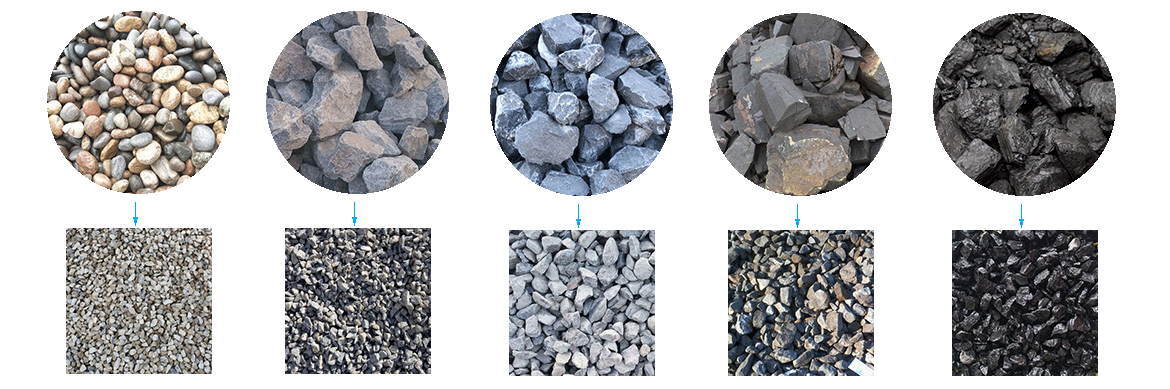

The double roll crusher is mainly used to crush ores, which is suitable for feeding with particle size less than 80mm and finished products with particle size of 50 μ Fine crushing operation of m-20mm. For example, sand is artificially made from pebbles and construction waste; Mining fine iron ore and quartz; Broken raw materials in ceramic industry. It is applicable to the coarse and medium crushing of brittle block materials in cement, chemical industry, electric power, mining, metallurgy, building materials, refractory materials, coal mines and other industries.

Application of Double Roller Crusher

Double-roll crusher is widely used in the processing of various brittle and tough materials in cement, chemical industry, power station, mining, metallurgy, building materials, refractory materials, coal industry, etc.

Features of Double Roller Crusher

1. Compact structure, light weight and small volume.

2. Simple structure, small space occupation and convenient operation and maintenance.

3. The dust-proof plate is installed inside, with good sealing performance, less dust and low working noise.

Working principle of Double Roller Crusher

Each stick of the counter roll crusher is driven by a separate motor. A motor is also used to drive the stick of fixed bearing through belt drive, and the other end of the roller shaft of fixed bearing is equipped with a gear to drive the movable stick through the gear. The material is crushed.

Product Data

Technical Data of Double Roller Crusher:

| Model | Roller Diameter(mm) | Roller Width(mm) | Feeding Size(mm) | Discharging Size(mm) | Capacity(t/h) | Motor Power(kw) |

| 2PG400x250 | 400 | 250 | <35 | 2-8 | 2-10 | 5.5x2 |

| 2PG400x400 | 400 | 400 | <35 | 2-8 | 5-15 | 7.5x2 |

| 2PG610x400 | 600 | 400 | <40 | 2-8 | 10-20 | 15x2 |

| 2PG750x500 | 750 | 500 | <40 | 2-8 | 15-30 | 18.5x2 |

| 2PG800x600 | 800 | 600 | <40 | 2-8 | 25-40 | 22x2 |

| 2PGY1000x700 | 1000 | 700 | <60 | 2-8 | 35-60 | 30x2 |

| 2PGY1200x800 | 1200 | 800 | <60 | 2-8 | 50-100 | 45x2 |

| 2PGY1500x800 | 1500 | 800 | <80 | 2-8 | 90-140 | 90x2 |

| 2PGY1500x1000 | 1500 | 1000 | <80 | 2-8 | 120-180 | 110x2 |

| 2PGY1800x1000 | 1800 | 1000 | <100 | 2-8 | 160-240 | 160x2 |