Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

- Home

- Products

-

Stong Crushing Machine

- Jaw Crusher

- Impact Crusher

- Single Cylinder Cone Crusher

- Vertical Shaft Impact Crusher

- Wheel-type Mobile Crusher

- Crawler Type Mobile Crusher

- European Version Jaw Crusher

- Multi-cylinder Hydraulic Cone Crusher

- Compound(Symons) Cone Crusher

- Spring Cone Crusher

- Hammer Crusher

- Heavy Hammer Crusher

- Double Roller Crusher

-

- Projects

-

Beneficiation Production Line

Material Production

- Aggregate for Highway Building

- Wet Sand Making

- Manufactured Sand

- Limestone Crushing

- River Pebbles Sand Making

Other Production Lines

-

- Solutions

- News

- Services

- About

- Contact

Beneficiation Production Line

Iron Ore Processing Plant

Datetime:2021-07-08 19:21:44 Visits:

Raw Material:Iron OreCapacity:1-150t/h

Hot Sale:1-10T/H, 10-50T/H, 50-100T/H

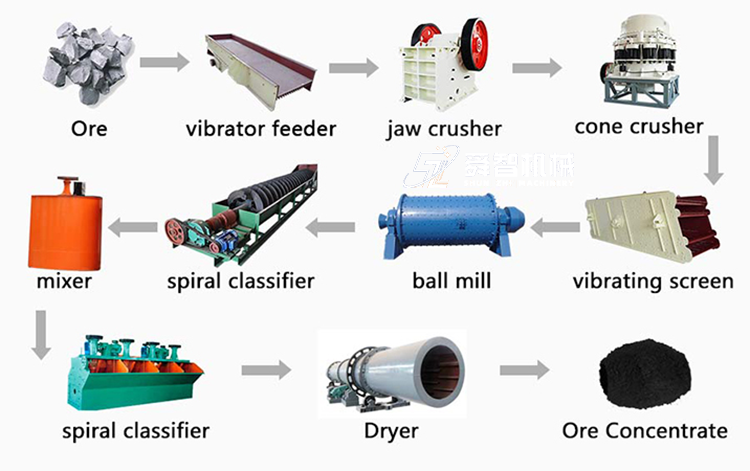

Processing Methods:Magnetic Separation Process

At present, the common iron ore is magnetite, limonite and hematite (collectively called weak magnetic ore). According to the magnetic strength of the ore, we choose different iron ore dressing processes. The magnetic separation process is used as the main method of iron ore beneficiation.

The iron ore process is advanced and the utilization rate of magnetite can reach 90%. And the configuration parts cited in the magnetite beneficiation production line are all wear-resistant materials, which can greatly improve the efficiency of the equipment.

Magnetic Separation Process

Related Equipment: Jaw Crusher, Ball Mill, Spiral Classifier, Magnetic Separator, Spiral Chute

Factors Affecting Magnetic Separation Process

1.Grinding And Classification Operations

In iron ore beneficiation plant, we should study its grinding work index according to its own ore characteristics and formulate a better set of grinding process parameters. Classification efficiency is a key factor affecting the operating efficiency of the mill.

2.Magnetic Separation Operation

Almost all iron ore beneficiation plants are inseparable from magnetic separation operations, and the efficiency of magnetic separators is an important factor affecting the beneficiation indicators of various beneficiation plants.