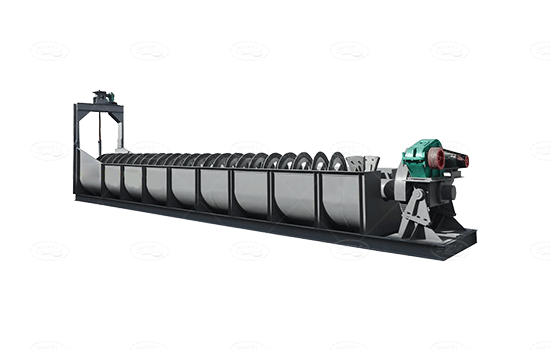

Spiral Classifier

Spiral Classifier

Capacity:10-900(t/d)

Moto Power:3-30(kw)

Spiral Diameter:300-3000(mm)

Processible Materials:Natural sand, artificial sand, machine-made sand.

Application:Clean mud and water or working with ball mill to control material size.

Features and technology advantages of Spiral Classifier

The spiral classifier is one of the equipment for mineral processing. The spiral classifier is a kind of equipment for mechanical classification based on the principle that the specific gravity of solid particles is different, so the speed of precipitation in liquid is different. It can filter the powder grinded out of the mill, and then screw the coarse material into the feed inlet of the mill with spiral blades, and discharge the filtered fine material from the overflow pipe. Screw classifier is referred to as classifier for short. Classifiers mainly include high weir type single screw and double screw, submerged type single screw and double screw.

Application of Spiral Classifier

It is widely used to form a closed cycle process to split mineral sand with ball mill in ore dressing plants, grade ore and fine mud in the gravity ore dressing plant, or for the pulp size classification in the metal beneficiation process, as well as desliming and dehydration in washing operations. Spiral classifier has the characteristics of simple structure, reliable work, convenient operation, etc.

Structure of Spiral Classifier

The spiral classifier of our company is mainly composed of transmission device, screw body, tank body, lifting mechanism, lower support (bearing bush) and ore discharge valve. The classifier produced by our company adopts advanced technology research and development, featuring simple structure, reliable work, convenient operation, etc.

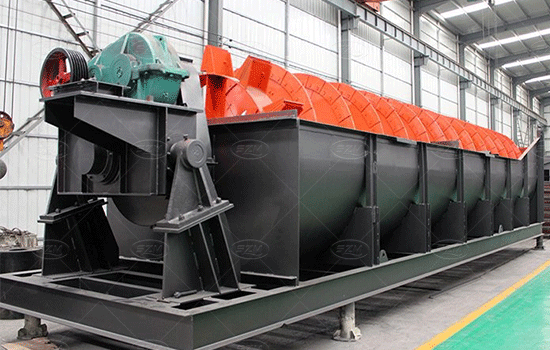

Advantages of Spiral Classifier

1. Large capacity, simple structure, low cost.

2. Reliable operation, convenient repair, good grading and washing effect.

3. It is the integration of washing, dehydration, desliming and controlling of the particle size, which is efficient and multi functional.

4. The screw axis has good wear resistance, fine granularity, excellent classification fineness, low anti sand rate.

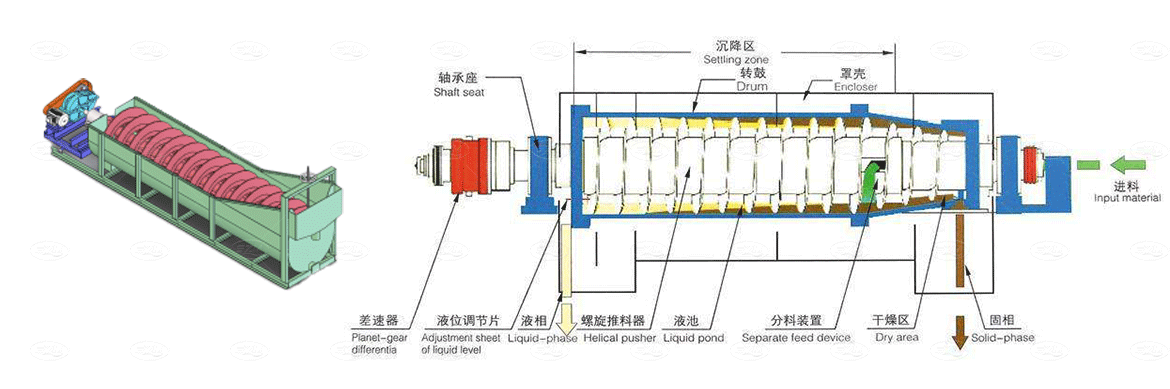

Working principle of Spiral Classifier

The spiral classifier is based on the principle that the size and specific gravity of solid particles are different, so the settling speed in the liquid is different [1]. Fine ore particles float in the water and overflow, while coarse ore particles sink at the bottom of the tank. A classification equipment that is used to carry out mechanical classification by pushing the screw to the upper part. It can grade the powder grinded in the mill to filter, and then screw the coarse material into the feed inlet of the mill by using the spiral vane to discharge the filtered fine material from the overflow pipe. The base of the machine is made of channel steel, and the body is welded with steel plate. The inlet head and shaft head of the screw shaft are made of pig iron sleeve, which is wear-resistant and durable. The lifting device is divided into electric and manual.

Product Data

Technical Data of Spiral Classifier:

Type

Model

Screw speed (r.p.m)

Treatment capacity according to sand return (t/d)

According to overflow treatment capacity (t/d)

Screw diameter (mm)

Tank length (mm)

Flume slope(°)

Drive motor model

Drive motor power (kw)

Model of lifting motor

Hoist motor power (kw)

Weight (kg)

Submerged single-screw classifier

FLC-1000

2.5,3.5,5,7.4

160-700

50~260

1000

8397

14-18

Y132M2-6

5.5

Manual

—

5225

FLC-1200

5,6,7

1150-1640

265

1200

8400

14-18

Y160M-6

7.5

Y90L-4

1.5

9583

FLC-1500

2.5,4,6

1140-2740

185

1500

10500

14-18

Y160L-6

7.5

Y100L1-4

2.2

14226

FLC-2000

3.6,5.5

3240-5940

400

2000

13000

14-18

Y160M-6

11

Y100L2-4

3

27753

Y160L-4

15

FLC-2400

3.6

6800

490

2400

14130

14-18

Y200L1-6

18.5

Y112M-4

4

32467

FLC-3000

3.2

11650

705

3000

14300

14-18

Y200L-4

30

Y112M-4

4

43500

Submerged double spiral classifier

2FLC-1200

3.8,6

1770-2800

240

1200

8400

14-18

Y160M-6

7.5×2

Y100L1-4

2.2×2

19610

2FLC-1500

2.5,4,6

2240-5360

370

1500

10500

14-18

Y160M-6

7.5×2

Y100L1-4

2.2×2

27450

2FLC-2000

3.6,5.5

7780-11880

640

2000

12900

14-18

Y160L-6/4

2×11,2×15

Y100L2-4

3.0×2

50621

Y200L2-6

22

Y200L-4

30

2FLC-2400

3.67

13700

910

2400

14130

14-18

Y225S-4

37

Y112M-4

4.0×2

65283

2FLC-3000

3.2

23300

1410

3000

14300

14-18

Y225M-4

45

Y112M-4

4.0×2

84900

High weir single screw classifier

FLG-300

7.7

30 ~80

10 ~30

φ300

3900

14 ~18

Y100L1-4

2.2

Manual

—

668

FLG-500

8

145~260

21 ~75

φ500

4390

Y112M-6

1600

FLG-750

7.8

100~445

31~165

φ750

5500

Y132S-6

3

2716

FLG-1000

6.7

473~1026

85

φ1000

6556

Y132M2-6

5.5

4000

FLG-1200

5,6,7

1145~1600

150

φ1200

6500

Y132M2-6

5.5

Y90L-4

1.5

7943

FLG-1500

2.5,4,6

1140~2730

235

φ1500

8265

Y160M-6

7.5

Y100L1-4

2.2

11827

FLG-2000

3.6,5.5

3240~5940

400

φ2000

8700

Y160L-6/4

11,15

Y100L2-4

3

20814

FLG-2400

3.6

6800

580

φ2400

9130

Y200L2-6

22

Y112M-4

4

24194

FLG-3000

3.2

11625

890

φ3000

12500

Y200L-4

30

Y112M-4

4

42188

High weir type double spiral classifier

2FLG-1200

5,6,7

2290~3200

310

φ1200

6500

Y132M2-6

5.5X2

Y90L1-4

1.5X2

15840

2FLG-1500

2.5,4,6

2240~5360

460

φ1500

8230

Y160M-6

7.5X2

Y100L1-4

2.2X2

22903

2FLG-2000

3.6,5.5

6400~10800

750

φ2000

8400

Y160L-4

15X2

Y100L2-4

3.0X2

34621

2FLG-2400

3.63

13600

1160

φ2400

9130

Y200L2-6

22X2

Y112M-4

4X2

42460

2FLG-3000

3.2

23300

1785

φ3000

12500

Y200L-4

30X2

Y112M-4

4.0X2

73030