Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

- Home

- Products

-

Stong Crushing Machine

- Jaw Crusher

- Impact Crusher

- Single Cylinder Cone Crusher

- Vertical Shaft Impact Crusher

- Wheel-type Mobile Crusher

- Crawler Type Mobile Crusher

- European Version Jaw Crusher

- Multi-cylinder Hydraulic Cone Crusher

- Compound(Symons) Cone Crusher

- Spring Cone Crusher

- Hammer Crusher

- Heavy Hammer Crusher

- Double Roller Crusher

-

- Projects

-

Beneficiation Production Line

Material Production

- Aggregate for Highway Building

- Wet Sand Making

- Manufactured Sand

- Limestone Crushing

- River Pebbles Sand Making

Other Production Lines

-

- Solutions

- News

- Services

- About

- Contact

Beneficiation Production Line

Silver Ore Beneficiation Plant

Datetime:2021-07-08 19:24:35 Visits:

Introduction of Silver Ore Beneficiation PlantSilver flotation process of Shunzhi includes three kinds of methods: flotation, flotation & gravity separation, flotation & cyaniding. While the flotation & cyaniding method is the most important process among the three. Silver concentrate can be get in the process of flotation, then regrinding to the next process including cyaniding and leaching, countercurrent washing, zinc powder replacement and silver ingot can be finally get after the last process of electrolytic dissociation. Thus the process characterized by high recovery and economic benefits.

Silver flotation process mainly applied for the recovery of silver and associated metallic minerals, including two categories: one is silver & gold , the other is copper, lead and zinc associated.

Process Description of Silver Ore Beneficiation Plant

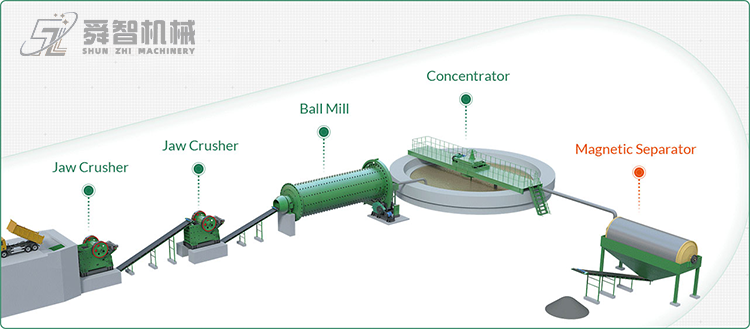

Equipment Used in the Extraction of Silver

The production line of flotation &cyaniding of Shunzhi mainly composed of flotation machine, leaching agitation tank, zinc powder replacement equipment, washing thickener of 2 or 3 layers. The production line characterized by high efficiency and capacity, low energy consumption and reasonable economic costs.

Process Advantages

To improve the recovery rate of the silver flotation process, Shunzhi developed the mineral processing in three methods. Firstly, due to the thickness features of the silver particles to dissociate silver totally to improve the recovery rate. Secondly, use neutral or weak alkalinity pump as well as the sodium carbonate as regulators to improve the floatability of silver. Thirdly, sodium n-butyl xanthate and sodium butyl aerofloat are mix-used to enhance the collecting ability to the silver. Similar to other mineral processing methods, silver flotation process also need to prepare materials bef separation. That is to say, the ore should be grinded and classified to suit the flotation fineness. Shunzhi also adopts the multi-layer thickener to dewater in three stages, and exchange the cyaniding process of one leaching and one dewatering into two of each, which highly improving the recovery rate of the silver. Shunzhi also use cyaniding to process Hydrogen-containing wastewater and to recover sodium cyanide, which proves to be a good method to solve the wastewater pollute. The alloy gold can adopt electrolyte equipment to dissociate silver, and get gold and silver ingot to improve the economic efficiency.