Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

- Home

- Products

-

Stong Crushing Machine

- Jaw Crusher

- Impact Crusher

- Single Cylinder Cone Crusher

- Vertical Shaft Impact Crusher

- Wheel-type Mobile Crusher

- Crawler Type Mobile Crusher

- European Version Jaw Crusher

- Multi-cylinder Hydraulic Cone Crusher

- Compound(Symons) Cone Crusher

- Spring Cone Crusher

- Hammer Crusher

- Heavy Hammer Crusher

- Double Roller Crusher

-

- Projects

-

Beneficiation Production Line

Material Production

- Aggregate for Highway Building

- Wet Sand Making

- Manufactured Sand

- Limestone Crushing

- River Pebbles Sand Making

Other Production Lines

-

- Solutions

- News

- Services

- About

- Contact

Beneficiation Production Line

Copper Processing Plant

Datetime:2021-07-08 19:22:50 Visits:

Raw Material:Copper OreCapacity:1-150t/h

Hot Sale:1-10T/H, 10-50T/H, 50-100T/H

Processing Methods:Flotation Separation Process

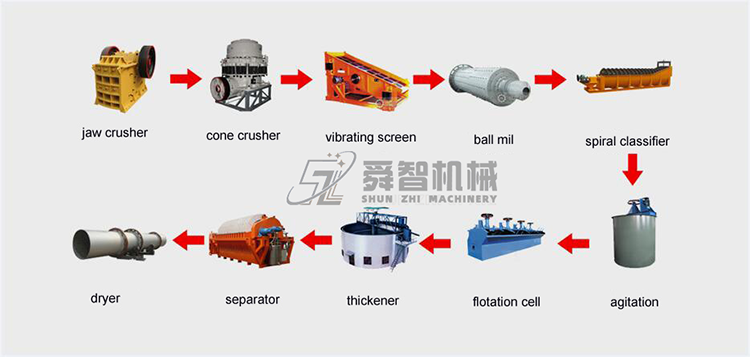

Flotation separation process is often used in the copper ore processing plant. Before the flotation of the medicine, the copper ore is coarsely ground into small pieces, and then ground to a certain particle size, and then the beneficiation agent is added therein. In this way, the ore particles float up, and the final foam product is collected and further dehydrated to obtain copper concentrate, which is sent to the smelter for copper smelting.

Flotation equipment is mainly flotation machine and other equipment to realize flotation process. Flotation machine is made up of many cells in series. Shunzhi Machinery has different types of flotation machines available, such as SF flotation machine, XCF flotation machine, KYF flotation machine, BF flotation machine.

Flotation Separation Process

Related Euipment: Jaw Crusher, Ball Mill, Spiral Classifier, Magnetic Separator, Flotation Machine

Factors Affecting Flotation Process

1.Copper Ore Grinding Fineness

The upper limit of particle size is 0.25mm and the lower limit is 0.01mm. If the particle size is less than 0.01mm, the ore will be crushed and slimed, which will worsen the flotation index.

2.Pulp Concentration

Pulp concentration is thin, recovery is low, but concentrate quality is high. With the increase of pulp concentration, the recovery rate increases. When it reaches a certain level, the recovery rate will decrease with the increase of pulp concentration. Generally, pulp concentration is 25-35%

3.Flotation Time

If the time is too long, the recovery rate will increase, but the concentrate grade will decrease; if the time is too short, the concentrate grade will be favorable but the tailings grade will increase.