Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

- Home

- Products

-

Stong Crushing Machine

- Jaw Crusher

- Impact Crusher

- Single Cylinder Cone Crusher

- Vertical Shaft Impact Crusher

- Wheel-type Mobile Crusher

- Crawler Type Mobile Crusher

- European Version Jaw Crusher

- Multi-cylinder Hydraulic Cone Crusher

- Compound(Symons) Cone Crusher

- Spring Cone Crusher

- Hammer Crusher

- Heavy Hammer Crusher

- Double Roller Crusher

-

- Projects

-

Beneficiation Production Line

Material Production

- Aggregate for Highway Building

- Wet Sand Making

- Manufactured Sand

- Limestone Crushing

- River Pebbles Sand Making

Other Production Lines

-

- Solutions

- News

- Services

- About

- Contact

Other Production Lines

Oil Fracturing Proppant Production Line

Datetime:2021-07-08 19:31:27 Visits:

Capacity:10000-50000(t/a)Main Materials:bauxite, manganese powder and additives

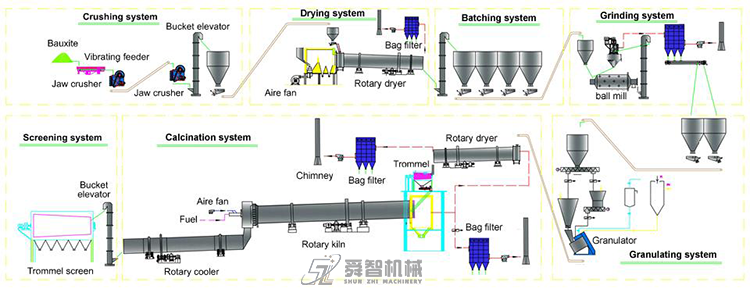

Main Equipment:Bauxite Crusher, Proppant Kiln, Ball Mill, Screen, Granulator etc

Application: Well Fracking

Ceramic proppant, known as petroleum fracturing proppant, is one new type of material made from bauxite, manganese powder and additives by the process of crushing, drying, batching, pelletizing, calcining, cooling and sieving. Ceramsite proppant has the advantage of high strength, compression and abrasion resistance, good roundness, shock resistanceand good permeability resistance.

We not only supply the complete set of equipment for Fracturing Proppants Production Line, but also supply different sepcifications of ceramic proppants.

Ceramic Proppant Specification

Model 1: 0.45-0.9mm (20 mesh-40 mesh) high intensity and middle density

Model 2: 0.9-1.25mm (16 mesh-20 mesh) high intensity and middle density

Model 3: 1.0-1.70mm (12 mesh-18mesh) high intensity and middle density

Model 4: 0.224-0.65mm (40mesh-60mesh) high intensity and middle density

Advantage of Oil Fracturing Proppant Production Line

1.Advanced Pelletizing System

The SZZL granulator developed by our company is special equipment for pelletizing in the ceramic proppant production process, which has the advantages of high production efficiency, full automation control, and no dust pollution.

2.Complete Set of Granulation Experimental System

We owns a complete set of granulation experimental production line, which can conduct experiments on customers' incoming materials, find out the best granulation technology for the materials, and give guidance for actual production.

3.Environmental Protection

Two phases of dust collection including cyclone filter and bag filter, will control the dust emission below the limitation of the national standard.

4.High Degree of Automation

Rotary cooler at the discharge end of rotary kiln recycles the heat of Oil fracturing proppant which is discharged from the rotary kiln, and will preheat the secondary air up to 500℃.

Production Technology of Oil Fracturing Proppant Production Line

Since 2005, Henan Shunzhi Machinery Co., Ltd began to supply equipment and services for the ceramsite sand industry. Copperated with Henan Metallurgical Planning & Design Institute, Zhengzhou Light Metal Research Institute and Zhengzhou University Mechanical Engineering College, we set up a more than 20 people R&D team, developed new type high efficiency granulators.

During the research and development, we test more than 10 different raw materials, more than 100 tons of different raw materials. More than 10,000 times pelletizing experiments were conducted, thus we accumulated a large amount of primary information to continuously improve equipment performance and improve product functionality. The SZZL granulator developed by our company is special equipment for pelletizing in the ceramics industry, which has the advantages of high production efficiency, full automation control, and no dust pollution.

Bauxite will be firstly crushed by jaw crusher and hammer crusher and then it will be conveyed to batching silo. After batching with other material, materials will be sent to ball mill and grinded into powder. Classifier will be used after ball mill for size grading. Here raw material will be sent to silo again. Then raw material will go to granulator and will be made into different size pellets. Pellets will be sent to screening equipment. Qualified size pellets will be conveyed to rotary kiln for calcination. Oversize pellets will be sent back for grinding.

After pellets calcined in rotary kiln, we get qualified product ceramic sand. At last, ceramic will go to cooler for cooling. And will go to screen to get different size oil fracturing proppant and will be packed in ton bag. The production process ends.