Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

- Home

- Products

-

Stong Crushing Machine

- Jaw Crusher

- Impact Crusher

- Single Cylinder Cone Crusher

- Vertical Shaft Impact Crusher

- Wheel-type Mobile Crusher

- Crawler Type Mobile Crusher

- European Version Jaw Crusher

- Multi-cylinder Hydraulic Cone Crusher

- Compound(Symons) Cone Crusher

- Spring Cone Crusher

- Hammer Crusher

- Heavy Hammer Crusher

- Double Roller Crusher

-

- Projects

-

Beneficiation Production Line

Material Production

- Aggregate for Highway Building

- Wet Sand Making

- Manufactured Sand

- Limestone Crushing

- River Pebbles Sand Making

Other Production Lines

-

- Solutions

- News

- Services

- About

- Contact

Beneficiation Production Line

Nickel Ore Processing Plant

Datetime:2021-07-08 19:23:09 Visits:

Material:Nickel Ore Capacity:1-150t/h

Application: suitable for copper-nickel ore or nickel oxide ore with pyrite and other kinds of gangue

Processing Method: flotation separation processing, magnetic separation processing, etc

Nickel resources are mainly distributed in Cuba and Brazil in the Americas; Indonesia and the Philippines in Southeast Asia; Australia, New Caledonia and Papua New Guinea in Oceania. Nickel ore has good mining, beneficiation and smelting value. Common types include nickel oxide ore, nickel sulfide ore and so on. Nickel ore is mainly divided into copper sulfide nickel ore and nickel oxide ore. Rich ore containing more than 3% nickel can be directly smelted; ore containing less than 3% nickel needs to be processed. Shunzhi Machinery's beneficiation method in processing copper-nickel sulfide ore is mainly flotation, while magnetic separation and gravity separation are usually auxiliary beneficiation methods.

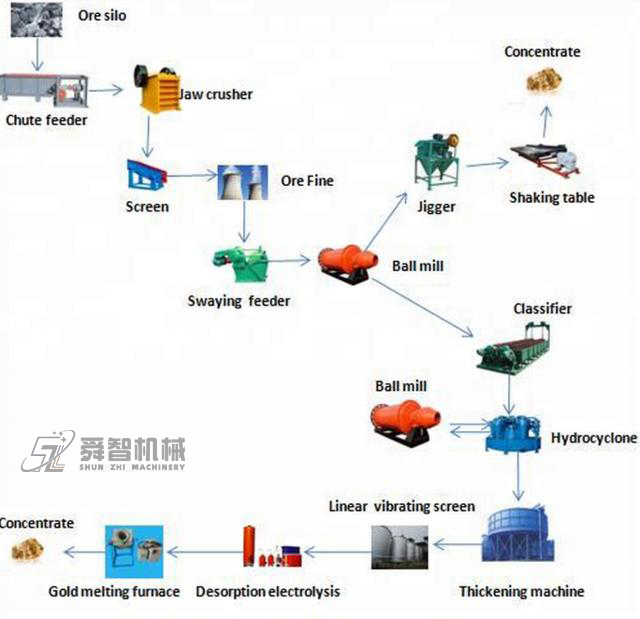

Nickel Ore Flotation Processing Flowchart

The nickel ore beneficiation production line is mainly divided into three stages: crushing, grinding, and flotation. The equipment used includes jaw crusher, nickel ore ball mill, nickel ore flotation machine, rotary dryer, spiral classifier, etc.

Advantages of Nickel Ore Processing Plant

Reducing the Investment Cost:

The equipment configuration of the entire production line is reasonable, and all equipment is developed and designed by Shunzhi Machinery, which are all factory prices, reducing the investment cost of customers.

High Flotation Efficiency:

The flotation process is simple, the flotation time is long, and the number of selections is small. The nickel concentrate grade is generally 4-8%, and the higher one can reach 13-15%.

Energy Saving and Environment Protection:

The electric motor equipment imported from Germany is selected and the centralized electric control system is designed, and the energy saving effect is particularly significant.