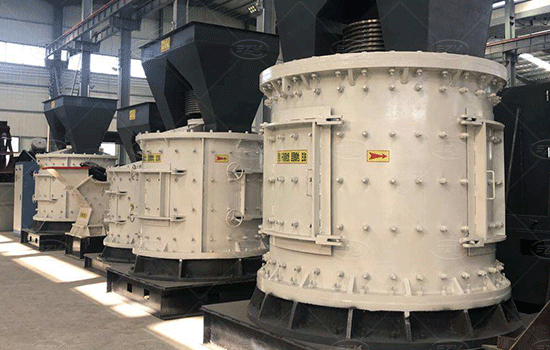

Vertical Compound Crusher

Vertical Compound Crusher

Feeding Size:50-100(mm)

Motor Power:22-355(kw)

Capacity:5-100(t/h)

Applied Materials:Coal, limestone, granite, cobble, dolomite, bluestone, iron ore, coal gangue, coal, activated carbon, quartz, basalt, etc

Features and technology advantages of Vertical Compound Crusher

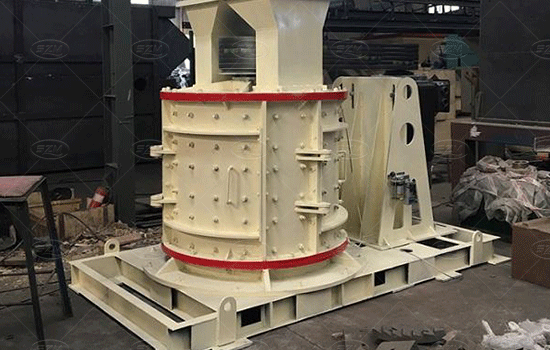

Vertical compound crusher is a kind of small rock crusher, which is suitable for crushing limestone, clinker, coal and other minerals in building materials industry, mining, metallurgy and chemical industry.

The compressive strength is less than 140 MPa, and the humidity of materials is not more than 15%. Compound crusher has unique features of large production capacity, big crushing ratio, low energy consumption, good sealing effect, stable operation and easy maintenance.

Applications of Vertical Compound Crusher

It is widely used for the fine crushing of raw meal and clinker in cement plants, and also for the fine crushing of medium-hard materials such as dolomite, pyrolite, lead-zinc ore, serpentine, blast furnace slag, coal gangue, phosphate rock, etc., especially for the processing and crushing of hard limestone, dolomite, granite, Xuanwu rock and other artificial sand or highway pavement stones.

Advantages of Vertical Compound Crusher

1. Big crushing ratio, high efficiency and energy saving. Compound crusher has fine and coarse grinding functions. It has characteristics of small wear, simple and reasonable structure, low operation cost, high rushing rate and energy saving.

2. Not easily affected by the moisture content of material with convenient maintenance. Less affected by the moisture content of materials and moisture content can reach up to about 8%. Impeller lining has small wear, which is convenient for maintenance.

3. Uniform product size, less pollution. The working noise is less than 75 dB (DB level), less dust pollution. The finished product is in cubic shape, large bulk density and minimal iron pollution.

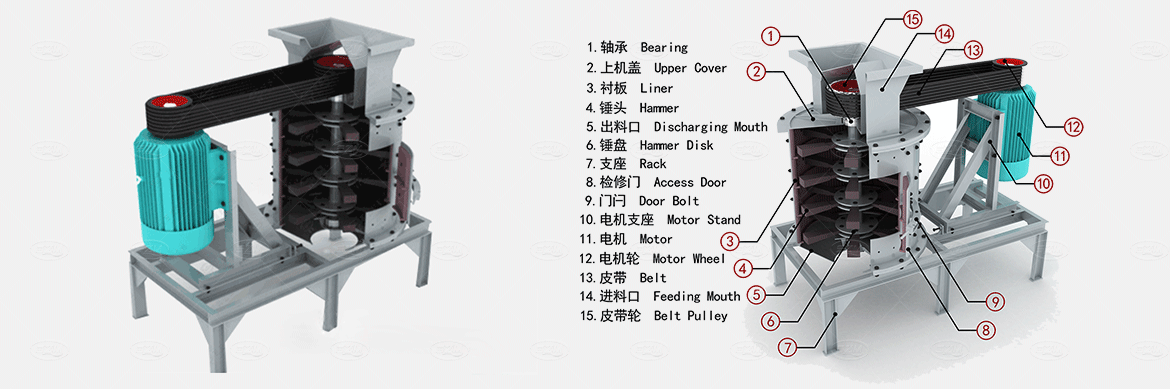

Working principle of Vertical Compound Crusher

Product Data

Technical Data of Vertical Compound Crusher:

Model

Capacity(t/h)

Motor power(kw)

SZLZP-800

5-15

4P 30

SZLZP-1000

10-30

4P 55

SZLZP-1250

17-60

6P 132

SZLZP-1500

25-80

8P 160

SZLZP-1750

30-100

8P 200