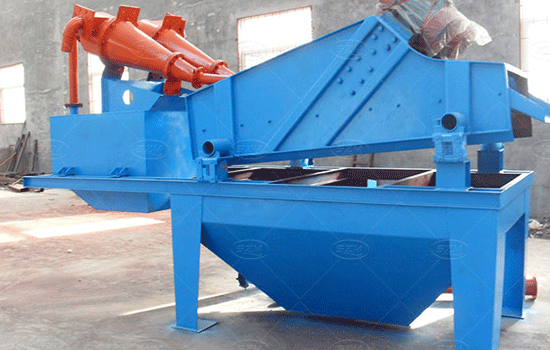

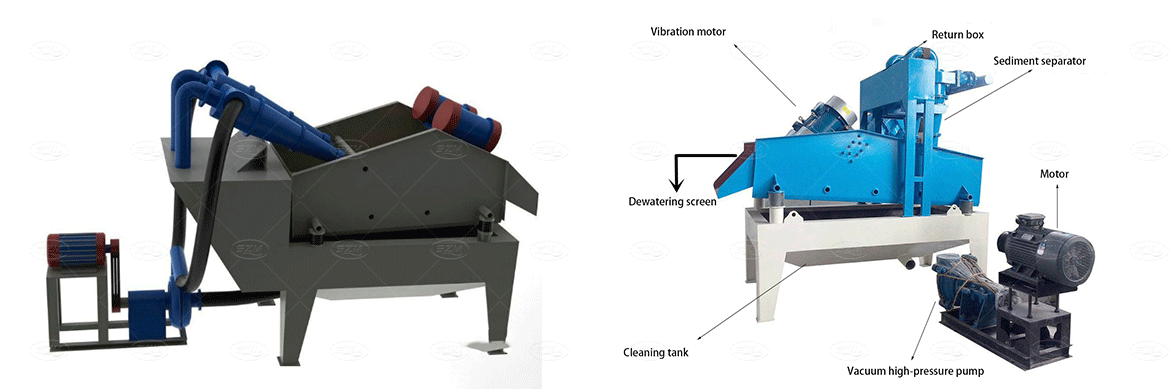

Fine Sand Recovery Machine

Fine Sand Recovery Machine

Weight:3-19(t)

Power:11-75(kw)

Capacity:30-600(t/h)

Cyclone Specification:300-750(mm)

Features and technology advantages of Fine Sand Recovery Machine

The fine sand reclaimer is a kind of equipment developed for slurry material dehydration, disintermediation and desliming. The greatest feature of this machine is that it can well solve the problem of fine sand loss in the sand making industry. Fine sand reclaimer is also called tailing sand reclaimer, fine sand extractor, fine sand collector, sediment separator, mud separator, sand water mixture treatment system, etc.

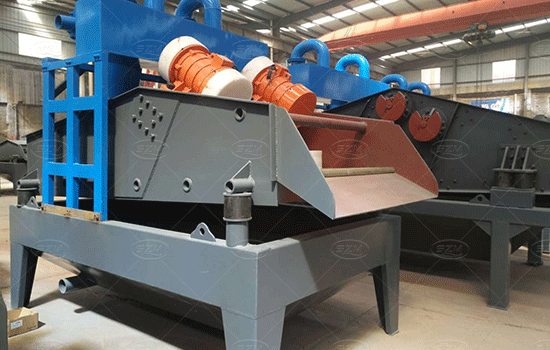

Application of Fine Sand Recovery Machine

The equipment is widely used in the processing system of sand and stone aggregate of the hydropower station, the processing system of glass material, the production line of artificial sand, the recovery of coarse slime in the coal preparation plant, and the environmental protection engineering (mud purification, etc.), which can effectively solve the problem of the fine sand recovery of the production line.

Advantages of Fine Sand Recovery Machine

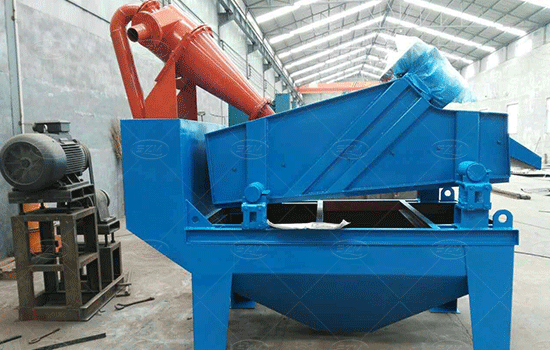

1. Vibrating screen adopts Polyurethane screen mesh, which has long lifetime and is not easy to block up the hole.

2. The inner part of swirler has polyurethane, which improves the lifetime of whole equipment, and finish slurry concentrator and fluide clarifiant.

3. Fine sand recovery system can recover 85% of the whole fine particle, and has technological and economical advantages.

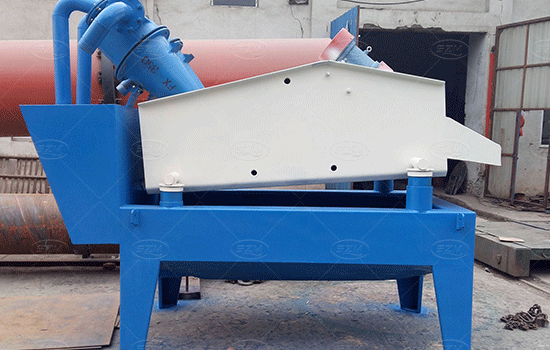

4. The fine particle can recover abundantly and reduce the work of settling pond and lower the cost of clearing the pond.

5. Fine sand recovery system can lower time of natural settling sand and provide the market.

6. We can design the project according to the customer’s need.

Working principle of Fine Sand Recovery Machine

Product Data

Technical Data of Fine Sand Recovery Machine:

Model

Separator Specification

Size of Dewatering Screen(mm)

Dehydration Screen Power(kw)

Type of Pump

Pump Power(kw)

Capacity(tph)

SZ8018

250

800*1800

0.75*2

2-3

11

5-10

SZ1020

300

1000*2000

1.1*2

3-4

15

10-20

SZ1225

350

1200*2500

2.2*2

3-4

15

20-30

SZ1530

350*2

1500*3000

3.0*2

3-4

15*2

50-80

2SZ1530

350*2

1500*3000

3.7*2

3-4

15*2

50-100

SZ1840

350*2

1800*4000

3.7*2

3-4

15*2

100-130

2SZ1840

350*2

1800*4000

3*4

3-4

15*2

100-150

SZ2050

500*2

2000*5000

3.7*4

3-4

18.5*2

150-200

2SZ2060

500*2

2000*6000

3.7*4

2-3

22*2

200-260