Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

Henan Shunzhi Machinery Equipment Co., Ltd

Special mine equipment of various specifications

Professional technical team solutions

Quality after-sales service

Material Production

Diabase Crushing

Datetime:2021-07-08 19:27:22 Visits:

Design OutputAccording to customer needs

Material

Diabase

Application

Mining, metallurgy, construction, highway, railroad, and water conservancy, and etc.

Equipments

Jaw Crusher, Hydraulic Cone Crusher, Vertical Shaft Impact Crusher, Vibrating Screen and Vibrating Feeder.

Diabase composition is equivalent to gabbro's hypabyssal rock, which is superior building material. It can be used as building stone or craft stone. It is the raw material of casting stone. Even texture, no cracks can be used as stone materials, fine-grained is preferred.

Basic Process of Diabase Crushing Production Plant

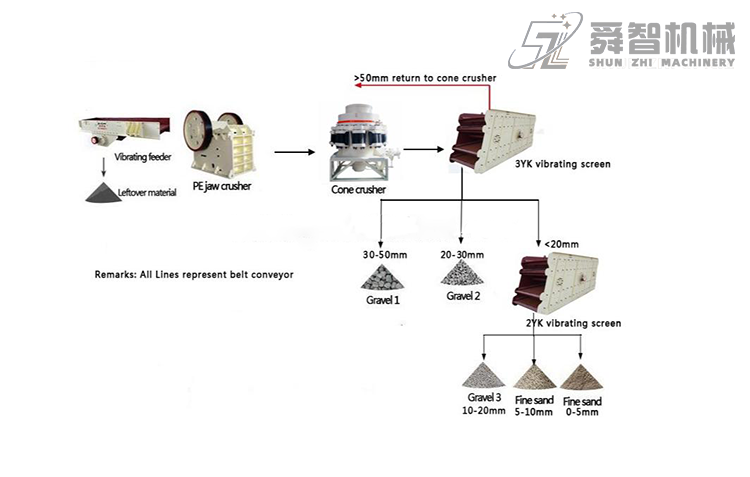

The Basalt crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening.

The first stage: coarse crushing

The diabase stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing.

The second stage: medium and fine crushing

The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium and fine crushing.

The third stage: screening

The medium and finely crushed stones are conveyed to the vibrating screen through a belt conveyor to separate stones of different specifications. The stones that meet the requirements of the customer's particle size are conveyed to the finished product pile through the belt conveyor. The impact crusher crushes again, forming a closed circuit cycle.

Basic Process of Diabase Sand Making Plant

The diabase sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and sieving.

The first stage: coarse crushing

The diabase stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing.

The second stage: medium broken

The coarsely crushed materials are screened by vibrating screen and then conveyed by belt conveyor to cone crusher for medium crushing. The crushed stones are conveyed to the vibrating screen through a belt conveyor to sieve out different specifications of stones. The stones that meet the requirements of the customer's particle size are conveyed to the finished product pile through the belt conveyor. The cone crusher crushes again, forming a closed circuit cycle.

The third stage: sand making

The crushed material is larger than the size of the two-layer screen, and the stone is conveyed to the sand maker machine through the belt conveyor for fine crushing and shaping.

The fourth stage: screening

The finely crushed and reshaped materials are screened by circular vibrating screen for coarse sand, medium sand and fine sand.

Note: For the sand powder with strict requirements, a sand washing machine can be added behind the fine sand. The waste water discharged from the sand washing machine can be recovered by the fine sand recycling device. On the one hand, it can reduce environmental pollution, and on the other hand, it can increase sand production.