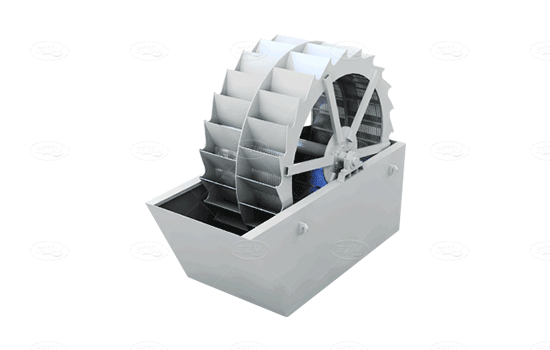

Sand Washing Machine

Sand Washing Machine

Power:4-11(kw)

Capacity:15-200(t/h)

Input Size:≦10(mm)

Application:Sand washing machine is widely used for cleaning the crushed materials in quarry, mining, construction, chemical industry, cement mixture station and so on

Features and technology advantages of Sand Washing Machine

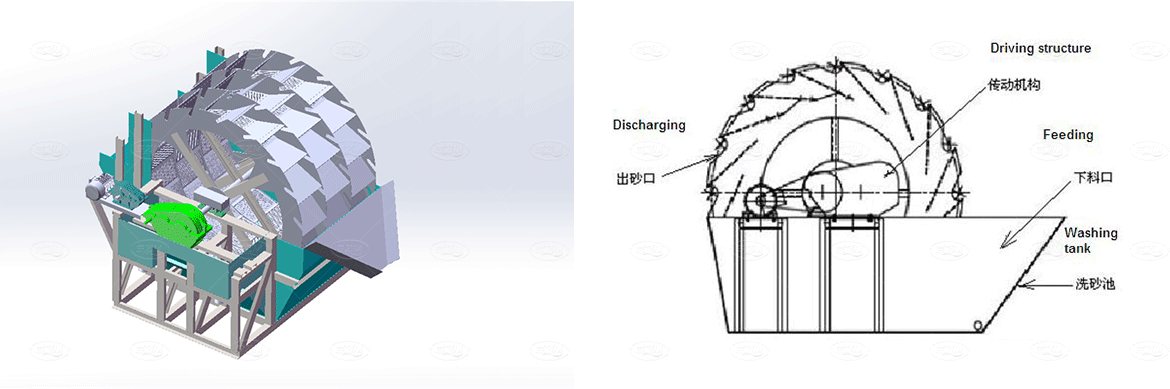

Sand washing machine, also called sand washer machine and silica sand washing machine, is a kind of washing equipment for artificial and natural sand. It is one of the major equipment of sand production line. The main task of this equipment in sand production line is to clean the crushed sand materials.

Simply put, Sand washing machine is used to remove the dust and stone powder in the sand produced by sand making machine, it also can do sand-selecting work or the similar process. The machine aims at improve the quality and grade of the sand.

Application of Sand Washing Machine

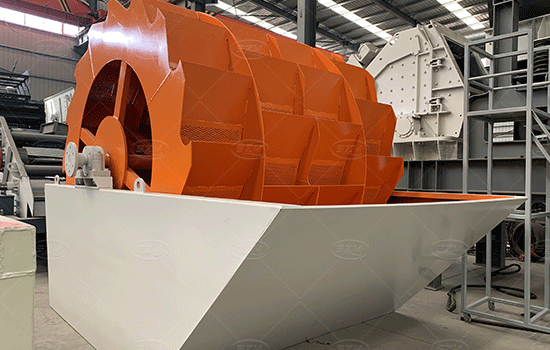

1. Sand washing machine is widely used to wash and select materials in sand and gravel field, mining, construction materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station, etc.

2. It is also can be applied to wash, select, classify, and dehydrate smaller particles required in construction site, sandstone factory, glass factory, hydropower station and other units. This machine has advantages of high cleanliness degree, reasonable structure, large capacity, low consumption, less sand loss in the washing process, etc.

3. Sand washer generally goes with sand maker. It can improve the quality of sand by removing the trace of stone powder and impurities mixed in the sand out of the sand maker. Sand making machine, sand washing machine, vibrating screen, feeder and crusher machine are all indispensable in sand production line.

Advantages of Sand Washing Machine

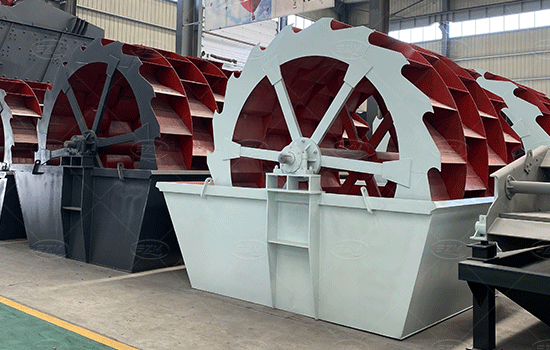

1. Long service life and low maintenance cost. With simple structure, isolation of impeller transmission bearing device from water and water material greatly protects the bearing device from damage from water, pollution, etc.

2. Less sand loss and high cleanliness degree.The grading and fineness modulus of the sand in washing machine meets the requirement in Specification of Sand for Building and GB code "Structural purpose Pebbles, Crushed Stone".

3. Large production capacity. Combined special roller with efficient side feeding system, production capacity and product quality are improved.

4. Reasonable structure and reliable operation. Fully sealed oil-bath driving system and adjustable overflow plate ensure a high and efficient production and easy cleaning.

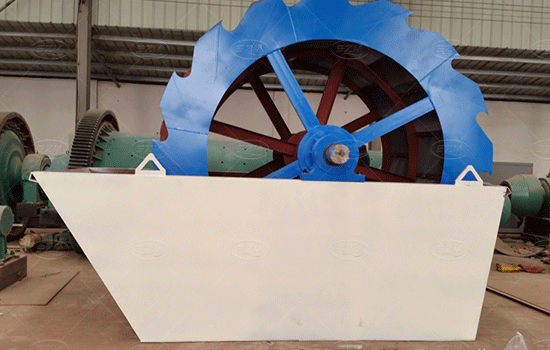

Working principle of Sand Washing Machine

When XSD sand washing machine begin running, the impeller rotates slowly drived by motor and reducer, sand and gravel from the feed chute into the wash tank cleaning, rotation of the impeller take the water and sand away through the sieve filter out the clean sand. Finally, gravel from the rotating impeller into discharge chute and completion of gravel cleaning effect.

Product Data

Technical Data of Sand Washing Machine:

Model

Feeding Size (mm)

Capacity (t/h)

Impeller Size (mm)

Power (kw)

Overall Size (mm)

XSD1808

≤10

20-40

1800*800

3

3000*2400*1900

XSD2512

≤10

30-80

2500*1200

4

3900*2900*2700

XSD3016

≤10

60-120

3000*1600

5.5

4400*3300*3100

XSD3620

≤10

80-160

3600*2000

7.5

5100*3750*3700

XSD3624

≤10

120-200

3600*2400

11

5100*4100*3700