Contact us for more information +86 173 989 56111 or szm@chinashunzhi.com

Henan Shunzhi Machinery Equipment Co., Ltd

Special mine equipment of various specifications

Professional technical team solutions

Quality after-sales service

Beneficiation Production Line

Tin Ore Beneficiation Plant

Datetime:2021-07-08 19:24:12 Visits:

Material:Tin Ore Capacity:1-150t/h

Application: tin lead ore, tin tungsten ore, tin zinc ore, tin molybdenum ore, tin iron ore, tin copper ore, etc.

Processing Method: gravity, flotation or magnetic separation

Because the density of tin ore is higher than that of symbiotic minerals, the traditional process of tin ore beneficiation is gravity beneficiation. The particle size of tin mineral in the selected ore becomes finer, and the tin can be floated. Since various iron oxide minerals often exist in tin minerals, such as magnetite, hematite, and limonite, these minerals cannot be separated from tin stone well by flotation and gravity separation. Magnetic separation has appeared in the beneficiation process. Therefore, gravity, flotation and magnetic separation can be used for processing tin ore.

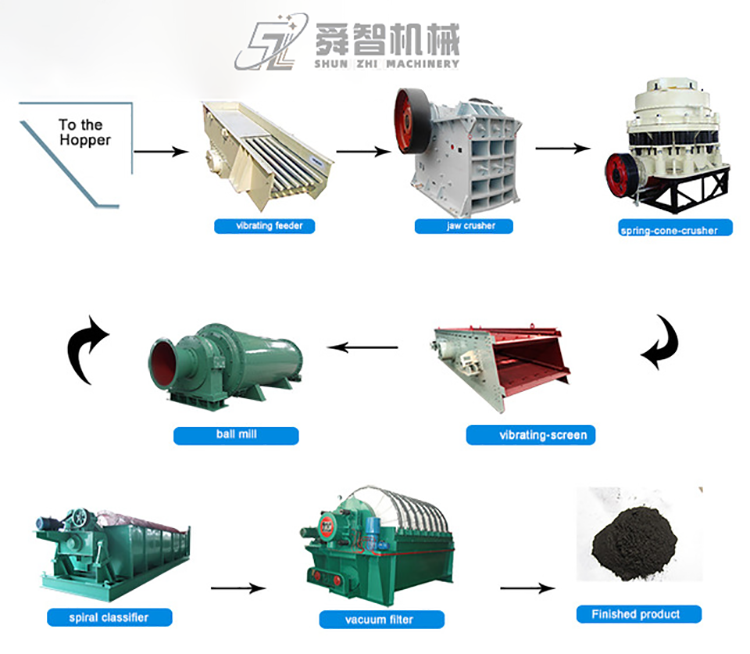

Process Description of Tin Ore Beneficiation Plant

Crushing and Screening

Crush the raw ore to 20mm, then screen it into two particle sizes, (20mm~4mm) and (4mm~0mm).

Preselecting

Put the 20~4mm ore into heavy medium cyclone to be selected. Then the ore will enter into the rod mill. After that, it will be preselected in jig. The tailings over 2mm will be abandoned, and the ore below 2mm will be put into shaking table.

Bulk Flotation

The concentration from jig and shaking board will be separately selected by bulk flotation. The tailings will enter the shaking board to get qualified tin concentrates.

Separating Flotation

After the bulk flotation, the concentrate will be fine grinded, then will be do the flotation separation of lead zinc ore. After that Lead antimony concentrates and zinc concentrates will be produced.

Gravity Separation

The tin pulp enter into Φ300mm hydrocyclone, then overflow to Φ125mm and Φ75mm hydrocyclone group to remove the fine mud. The sand setting will enter into the process of thickening, desulphurization by flotation, and then cassiterite flotation.

Advantages of Tin Ore Beneficiation Process

Reduce investment costs:

The price of the entire production line is about 3%-10% cheaper, and the space layout is scientific and compact, reducing the area of infrastructure and effectively reducing investment costs.

Smooth operation:

More stable operation, low noise and less pollution.

Low failure rate:

Low failure rate, large processing capacity, high degree of automation, and more convenient operation.

High grade tin concentrate:

The flotation effect is good, the grade of tin concentrate is increased by 30%, and the comprehensive utilization of resources is fully realized, which has significant economic and social benefits.