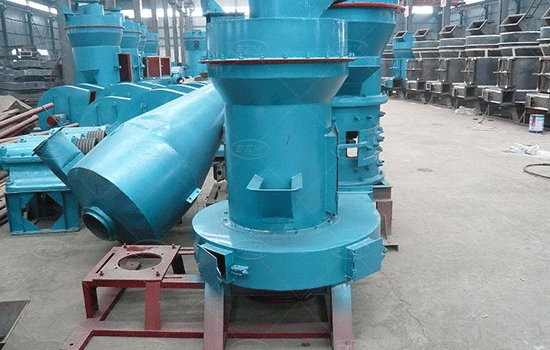

HGM Micro-powder Grinding Mill

HGM Micro-powder Grinding Mill

Capacity:1-45(t/h)

Max Feeding Size:<20(mm)

Final Product Size:300-2500(mesh)

Application:Dolomite and other more than 300 kids of minerals

Features and technology advantages of HGM Micro-powder Grinding Mill

HGM Micro-powder grinding mill is one of Raymond grinding machines. It is widely used in the grinding of mineral products and materials in the fields of metallurgy, building materials, chemical industry, mining, etc. The crushing range is: quartz, feldspar, porcelain clay, clay, bentonite, calcite, talc, barite, fluorite, clay, white mud, gypsum and other non-flammable and explosive mineral materials with hardness below Mohs 7 and humidity below 6%. It is classified and named according to the fineness of the ground material and the fineness of the discharged material.

Application of HGM Micro-powder Grinding Mill

pebble, limestone, granite, basalt, diabase, andesite, etc

HGM series of three-rings and medium-speed micro powder grinder is a new type of making micro powder machines through more than twenties times research and improvement, depending on two decades of hard work & experience and inputting the latest mechanical techniques of Sweden. It is an incorporated one of the two countries and a leader of the grinding industry nowadays.

Features of HGM Micro-powder Grinding Mill

1. High output: compared with other mills, the output of ultra-fine mill can be increased by 30% under the same power condition. If the spring pressure is increased, the power is correspondingly increased, the output will be higher.

2. Ultrafine grinding can mainly grind various mineral materials with Mohs hardness less than Grade 7, and the finished product has a wide range of fineness, with particle size up to 0.613 mm (30 mesh), particle size generally up to 0.033 mm (425 mesh), and a few materials can also reach 0.003 mm (3250 mesh).

3. Superfine grinding adopts overlapping multi-pole sealing grinding device, which has good sealing performance, no pollution, and the dust removal effect fully meets the national dust emission standard. It is a green and environment-friendly grinding equipment.

4. Compared with other similar mills, the grinding pressure of the grinding roller on the material is stronger.

Working principle of HGM Micro-powder Grinding Mill

In the main grinding chamber of ultra-fine powder mill, the grinding roller assembly is suspended on the grinding roller hanger through the cross arm shaft. The grinding roller hanger is fixedly connected with the main shaft and the blade holder. The pressure spring is tightly pressed on the outer end of the cantilever of the grinding roller bearing chamber by the tension rod. The cross arm shaft is used as the support point. The grinding roller is tightly pressed on the inner surface of the grinding ring by the spring pressure. When the motor rotates through the transmission device, the blade mounted on the blade holder rotates synchronously with the grinding roller, The grinding roller rolls on the inner surface of the grinding ring and rotates around itself. The analyzer drives the impeller of the analyzer to rotate through the motor drive device. The rotation speed of the analyzer determines the fineness of the powder.

Product Data

Technical Data of HGM Micro-powder Grinding Mill:

| Model | Average working diameter (mm) | Number of annular rolls/rolls | Main machine feeding size (mm) | Discharge size | Capacity(t/h) | Main power (kw) | Weight of main separator (t) | Dimension (mm) | ||

| Annular roll | Number of rolls | micron | mesh | |||||||

| HGM60 | 600 | 15 | 2 | ≤10 | 5-47 | 3250-325 | 0.35-2.5 | 37 | 5.2 | 10000x3000x5500 |

| HGM80 | 800 | 21 | 0.6-4 | 55 | 7 | 11900x2700x5800 | ||||

| HGM100 | 1000 | 27 | 0.9-6 | 110 | 9.5 | 15500x4500x8600 | ||||