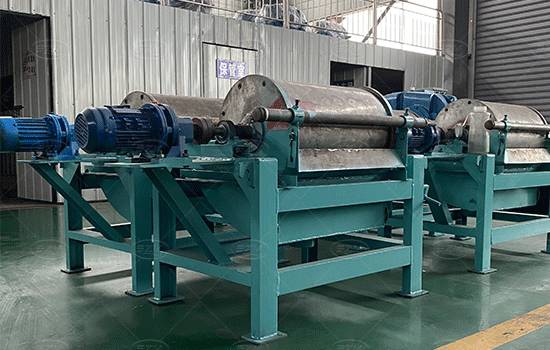

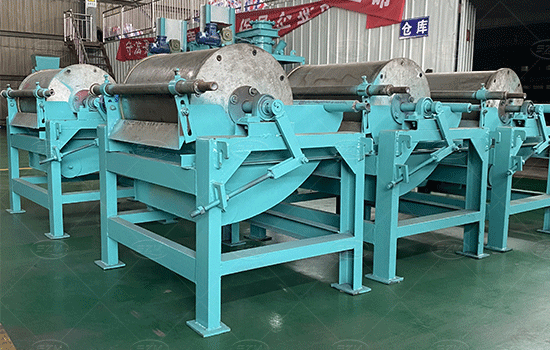

Magnetic Separator

Magnetic Separator

Capacity:1-350(t/h)

Feeding Size:0-3(mm)

Power:1.5-15(kw)

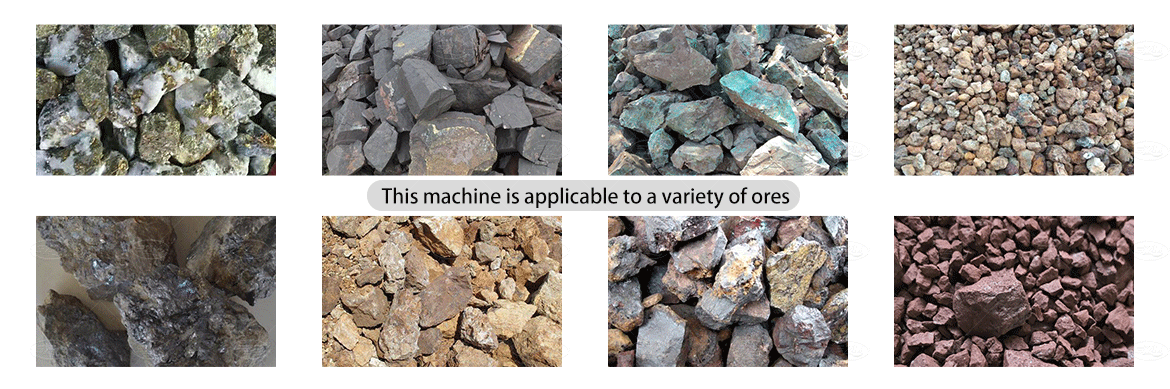

Application:Magnetite, pyrrhotite, roast ore and ilmenite and other materials with particle size less than 3mm. wet drum magnetic separator is also used for iron removal of materials such as coal, non-metallic minerals and building materials.

Features and technology advantages of Magnetic Separator

The magnetic separator is one of the most widely used and versatile machines in the industry. It is suitable for separating magnetic substances with magnetic differences. It is widely used in mining, wood industry, kiln industry, chemical, food and other industries. For the mining industry, the magnetic separator is suitable for wet or dry magnetic separation of manganese ore, magnetite, pyrrhotite, calcined ore, ilmenite, hematite and other materials with particle size less than 50mm, and also for iron removal of coal, nonmetallic ore, building materials and other materials. Magnetic separators are divided into two types. The magnetic system of permanent magnetic separators is mostly made of high-quality ferrite materials or composite with rare earth magnetic steel. In the early days, the average magnetic induction intensity on the magnetic cylinder surface of magnetic separators was 80-400mT. With the continuous development of technology, after the magnetic separator can be made into a roller shape, the magnetic field strength has also increased to 1650mT, which is the highest measured magnetic field strength at present.

Applications of Magnetic Separator

Magnetic separator is suitable for materials with magnetic difference, which is widely used for resource recovery, timber industry, mining industry, ceramics industry, chemical industry, food and other workshops. Magnetic separator is suitable for wet separating of materials with below 3mm particle size, such as magnetite, pyrrhotite, roasted ore, ilmenite and other materials. It is also used for iron removing operation of coal, non-metallic minerals, building materials and other materials, which is one of the most extensive and high versatility devices.

1. The magnetic system adopts NdFeB magnets with high magnetic energy product and high coercivity, which have high magnetic field strength and large action depth. The demagnetization rate of magnetic field strength in 8 years shall not exceed 5%.

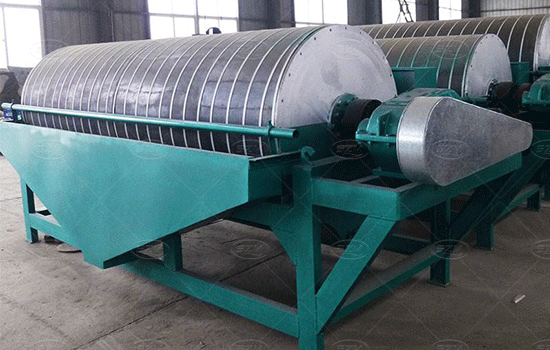

2. Large wrap angle magnetic system with gradual and smooth transition of field strength can increase the length of separation zone and the number of magnetic reversals to achieve efficient separation of magnetic minerals and non-(weak) magnetic minerals.

3. The magnetic system is covered with non-magnetic stainless steel to ensure that the magnet does not fall off.

4. According to different purposes and separation conditions, each series of magnetic separators has different magnetic system design and tank structure.

5. The tank structure is semi-countercurrent. It can also be made into a downstream tank according to sorting conditions and user requirements.

6. The cylinder is made of non-magnetic stainless steel and coated with wear-resistant rubber, which significantly improves the service life of the cylinder.

7. The permanent magnetic drum has strong adaptability to production, can withstand large fluctuations in feed volume, feed size and pulp concentration, and can obtain superior beneficiation indexes of high grade and high recovery at the same time.

8. Reasonable design, reliable operation and convenient maintenance.

Working principle of Magnetic Separator

After the pulp flows into the tank through the ore feed tank, under the action of the water flow of the ore feed spout pipe, the ore particles enter the ore feed area of the tank in a loose state. Under the action of magnetic field, the magnetic ore particles gather to form “magnetic group” or “magnetic chain”. The “magnetic group” or “magnetic chain” moves to the magnetic pole under the action of magnetic force in the pulp and is adsorbed on the cylinder. Because the polarity of the magnetic pole is alternately arranged along the rotation direction of the cylinder, and it is fixed when working, “magnetic mass” or “magnetic chain” is rotating with the cylinder, the phenomenon of magnetic agitation occurs due to the alternation of the magnetic pole, the gangue and other non-magnetic minerals mixed in the “magnetic mass” or “magnetic chain” fall off during the turning, and finally are absorbed in the “magnetic mass” or “magnetic Lotus” on the cylinder surface. The concentrate is transferred to the weakest magnetic field at the edge of the magnetic system along with the cylinder, and is discharged into the concentrate tank under the action of flushing water from the ore discharge pipe. Nonmagnetic or weak magnetic minerals are left in the slurry and discharged out of the tank with the slurry.

Product Data

Technical Data of Magnetic Separator:

Model

Cylinder diameter * cylinder length(mm)

Magnetic field strength of cylinder surface(GS)

Speed(r/min)

Capacity

Power(kw)

Weight(kg)

Dimension(mm)

Dry ore

Wet ore

(t/h)

(m³/h)

QCT(B/S/N)4040

400*400

2000-13500

45

1-2

3

1.5

150

1000*900*800

QCT(B/S/N)4050

400*500

2000-13500

45

1-3

5

1.5

220

1100*1000*900

QCT(B/S/N)4060

400*600

2000-13500

45

5-10

6

1.5

450

1200*1000*900

QCT(B/S/N)6066

600*600

2000-13500

40

8-15

16

2.2

480

1200*1100*1050

QCT(B/S/N)6069

600*900

2000-13500

40

10-20

24

3

550

1500*1100*1050

QCT(B/S/N)6012

600*1200

2000-13500

40

15-30

32

3

600

1800*1100*1050

QCT(B/S/N)6018

600*1800

2000-13500

40

15-30

48

3

860

2100*1200*1170

QCT(B/S/N)7512

750*1200

2000-13500

35

15-30

48

3

1050

2150*1450*1350

QCT(B/S/N)7518

750*1800

2000-13500

35

20-45

72

3

1250

2750*1450*1350

QCT(B/S/N)9018

900*1800

2000-13500

28

25-55

90

4

1610

2750*1670*1470

QCT(B/S/N)9024

900*2400

2000-13500

28

35-70

110

4

1810

3350*1670*1470

QCT(B/S/N)1018

1050*1800

2000-13500

22

40-75

120

5.5

1500

3100*1810*1650

QCT(B/S/N)1021

1050*2100

2000-13500

22

45-88

140

5.5

1810

3400*1810*1650

QCT(B/S/N)1024

1050*2400

2000-13500

22

52-100

160

5.5

2150

3700*1810*1650

QCT(B/S/N)1030

1050*3000

2000-13500

22

65-150

180

7.5

2900

4100*1950*1850

QCT(B/S/N)1218

1200*1800

2000-13500

19

47-90

200

7.5

2020

3650*2000*2000

QCT(B/S/N)1224

1200*2400

2000-13500

19

52-120

220

7.5

2700

3950*2100*2000

QCT(B/S/N)1230

1200*3000

2000-13500

19

80-150

240

11

3350

4200*2100*2000

QCT(B/S/N)1530

1500*3000

2000-13500

15

90-170

280

15

4640

4750*2200*2050

QCT(B/S/N)1536

1500*3600

2000-13500

15

120-140

300

15

4440

4750*2200*2050

QCT(B/S/N)1540

1500*4000

2000-13500

15

130-220

350

15

4800

5150*2200*2050