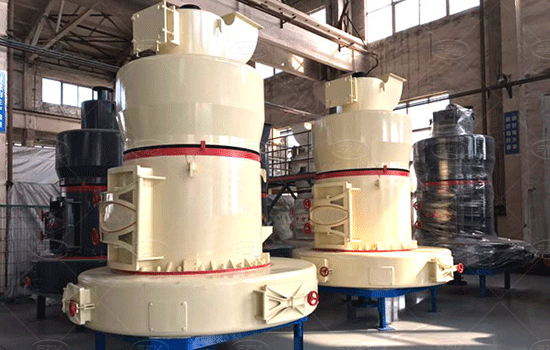

MTW European Version Mill

MTW European Version Mill

Capacity:1-30(t/h)

Max Feeding Size:20(mm)

Final Product Size:50-500(mesh)

Application:Feldspar, calcite, limestone, talc, barite, rare earth, marble, phosphate ore, kaolin, bentonite, gypsum, Perlite diatomite, dolomite etc

Features and technology advantages of MTW European Version Mill

The MTW raymond roller mill is used to grind materials in the fields of construction, mining, metallurgy and chemical industry. The materials should be non-flammable and non-explosive. Examples of the materials are: quartz, feldspar, barite, fluorite, dolomite, garnet, carborundum, bauxite, zircon, marble, calcite, iron ore, rock phosphate, coal, ceram, slag and so on (400 kinds of materials). The materials should have the hardness less than 9.3 in Moh’s scale and humidity less than 6 percent. The granularity of the end products can be changed from 30 to 425 meshes.

Application of MTW Micro-powder Grinding Mill

It crushing range is: quartz, feldspar, porcelain clay, clay, bentonite, calcite, talc, barite, fluorite, clay, white mud, gypsum and other non-flammable and explosive mineral materials with hardness below Mohs 7 and humidity below 6%.

Features of MTW European Version Mill

1.Reduce the roller and vibrate and improve the production volume according to the calculation, Regarding to the YGM series Raymond roller mill, under the sufficient grind force, the rollers is reduced and the grind space can be increased, The material layer filled better between the roller and ring, the attrition between rollers and rings is low, and the vibration and noise are also reduced, at the same time, the resistance of airflow of the fan becomes less. Winds can flow freely, thus the winds increase greatly, which determines the increase in the production volume. The production volume is 20% to 30% higher than R Raymond mill;2.The increase mechanism of linkage pressure of the rollers, which greatly prolongs the useful life of the equipment and increases the capacity by 20% under the same power;

3.With the original roller assembly, the oiling time increased 6 – 15 times, archive the application of oil once, use for 30-45 days;

4.High efficiency and stability, the ring and roller always contact during processing, the efficiency and stability of the grind are improved;

5.Higher Accuracy powder Classify, without coarseness missing, Variable frequency Squirrel cage classifier(Patent product) is adopted, the accuracy is 80-600 meshes. The classify efficiency reached 99%. The powder selection is stable and adjustable, compare with the blade type, it can greatly improve the powder selection efficiency and qualification rate of the Final product.

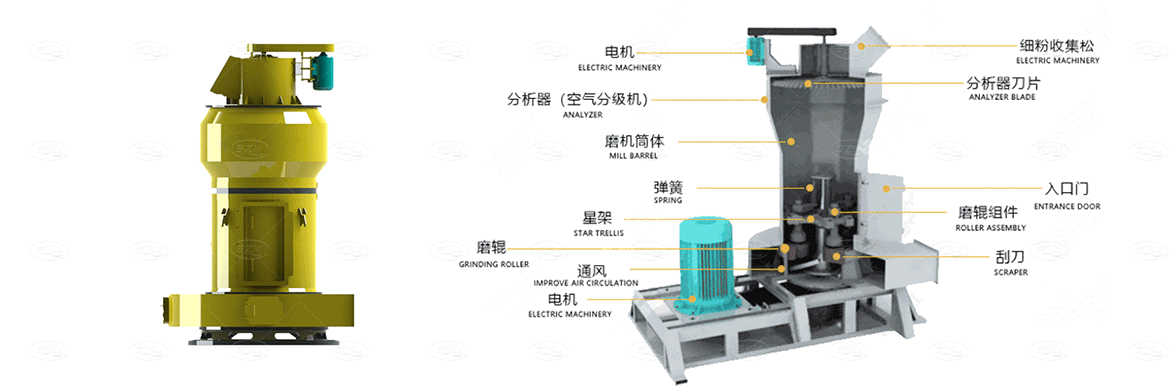

Working principle of MTW European Version Mill

The Raw materials by jaw crusher less than 20mm and lifted by the elevator to the storage hopper, then after vibrating feeder evenly and quantitatively and continuously into the Main machine grinding, grinded powder was blow by airflow away. Through the classifier separated, consistent with the powder fineness with air flow through the pipeline into the cyclone collector, were isolated and collected, and then by the powder in tube is discharged into the finished powder. Air flow from large cyclone collector is arranged at the upper end of the air return pipe suction blower. The air current of the whole system is a closed loop, and flow circulation in the positive and negative pressure condition.

Product Data

Technical Data of MTW European Version Mill:

Model

Inner diameter of grinding ring (mm)

Engine speed (r.p.m.)

Feed size (mm)

Discharge size (mm)

Capacity(t/h)

Motor power (kw)

Dimension (L x W x H) (mm)

Host

Siever

Fan

MTW110T

1100

120

≤30

1.6-0.045The smallest size can reach 0.038

5-47

3250-325

0.35-2.5

37

8425x7933x8642

MTW138T

1380

96

≤35

0.6-4

55

10920x9470x10227

MTW175T

1750

75

≤40

0.9-6

110

12195x9555x9916

MTW215T

2150

65

≤50

1.6-0.055 The smallest size can reach 0.045

0.9-6

110

13922x9810x13226