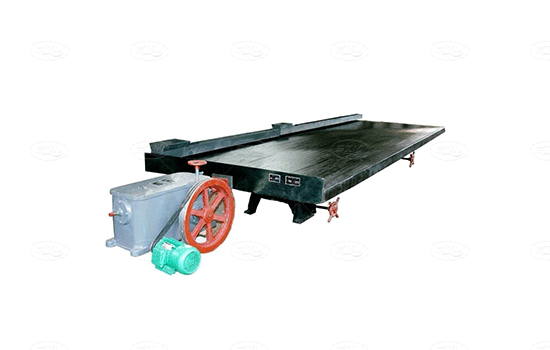

Shaking Table

Shaking Table

Capacity:0-60(t/d)

Feeding Concentration:15-30(%)

Feeding Size:0-2(mm)

Applied Materials:widely used for separating Tin, tungsten, gold and silver, lead, zinc, tantalum, niobium, iron, manganese, titanium iron and coal, etc.

Features and technology advantages of Shaking Table

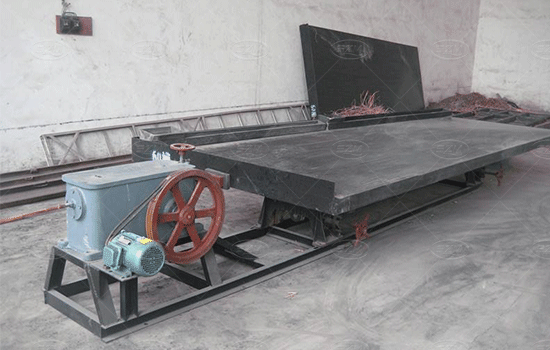

Shaker is a gravity beneficiation equipment used to separate fine materials, which is widely used to separate tin, tungsten, gold and silver, lead, zinc, tantalum, niobium, iron, manganese, ferrotitanium and coal.

Shaking table has been widely applied in many industries, which can conduct different working modes such as rough separation, fine separation and scavenging. It is suitable for separating gold, silver, tungsten, zinc, iron, manganese, lead, coal and other metal or heavy metal materials. Shaking table is suitable for 2-0.5mm coarse sand, 0.5-0.074mm fine sand and -0.074 slime in different granularity. When processing tungsten, tin and other metal ore materials, the effective recovery range of shaking table is 2-0.22mm.

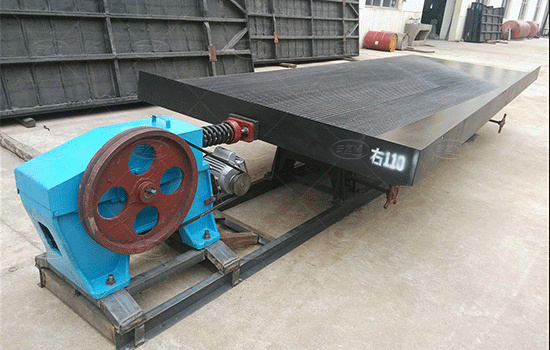

Features of Shaking Table

1. The operation is easy and the recovery rate is more than 90%.

2. The headstock mechanism is reliable in operation, with few easily worn parts and no oil leakage.

3. It is resistant to chemical corrosion, acid and alkali, and does not avoid mineral processing agents used in pulp.

4. No reagent consumption, high concentration rate, clean separation and low power consumption.

5. The sorting effect is excellent. It can select the sand gold and other elements in the river sand at one time.

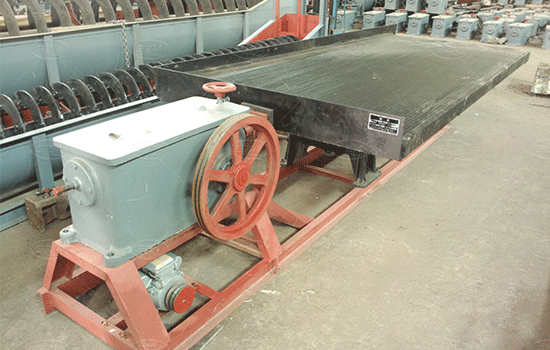

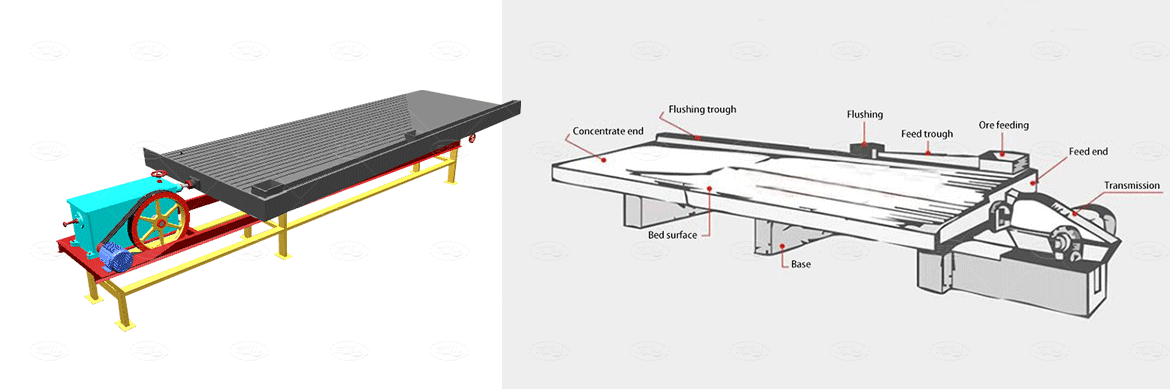

Working principle of Shaking Table

The motor drives the large belt pulley to drive the crankshaft rotary rocker to move up and down. When the rocker moves down, the elbow plate pushes the rear shaft and the reciprocating rod to move backward. The spring is compressed and the bed surface is connected with the reciprocating rod through the linkage seat. Therefore, the bed surface also moves backward at this time. When the rocker moves up, the bed surface moves forward due to the extension force of the spring.

Product Data

Technical Data of Shaking Table:

Name

Coarse sand shaker

Fine sand shaker

Slime shaker

Bed surface size

Length (mm)

4450

4450

4450

Drive end width (mm)

1855

1855

1855

Concentrate end width (mm)

1546

1546

1546

Maximum feed size (mm)

2

0.5

0.15

Ore feeding capacity (t/d)

30-60

10-20

15-25

Feed concentration (%)

25-30

20-25

15-25

Stroke (mm)

16-22

11-16

8-16

Frequency (f)

45-48

48-53

50-57

Bed cleaning water volume (t/d)

80-150

30-60

10-17

Cross slope of bed surface (°)

2.5-4.5

1.5-3.5

1-2

Cross slope of bed surface (°)

1.4

0.92

----

Bed surface pinch out angle (°)

32-42

40

42

Mineral processing area(㎡)

7.6

7.6

7.6

Bed surface length ratio

2.6

2.6

2.6

End face shape of bed surface

Rectangle

Sawtooth

Triangle

Motor power (kw)

1.1

1.1

1.1

Transmission mechanism

Eccentric linkage