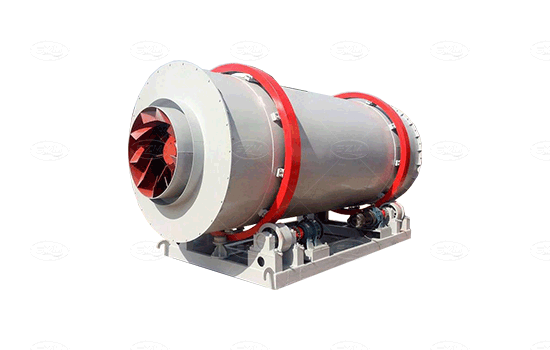

Three Drum Dryer

Three Drum Dryer

Capacity:25-30(t/h)

Diameter:1.6-3.6(m)

Rotation Speed:4-10(r/min)

Motor Power:11-90(kw)

Features and technology advantages of Three Drum Dryer

Introduction of Three Drum Dryer

Three drum dryer is also called three-cylinder dryer, whose main body is composed of three concentric circles of different diameters in inlaid combination. It is mainly used for drying granular material with certain humidity and certain particle size range, such as sand, molding sand, slag, cinder, fine-grained clay, high temperature resistant and dusty particles. The moisture content can reach 5 - 15% after the drying process.

The three cylinder dryer is mainly used for granularity material which is in the range of a certain humidity,such as yellow sand which used in dry mortar industry,all kinds of casting sand in casting industry,slag in building materials industry;also can dryingsmall granularity clay,coal,coal ash,iron powder,ore,silica sand and so on.

Features of Three Drum Dryer

1. The needed investment is only 1/6 of foreign import product.

2. The final moisture of the materials is ensured to be below 0.5%, making it the first choice of dry-mixed mortar and slag powder production line.

3. The self heat preservation heat efficiency of the cylinder can reach as high as over 70%, thus improving the heat efficiency by 35%.

4. The fuel can be coal, gas and oil, and it can be used for drying lump, granulous and powdery materials whose granularity is below 20mm.

5. Compared with single drum dryer machine, its floor space is reduced by about 50%, infrastructure investment reduced by about 50% and electricity consumption reduced by 60%.

6. The final water content can be easily regulated according to customers’ requirement.

7. The temperature of outing exhaust gas is low and the service life of the dust removing equipment is long.

8. It needs not rack wheel and pinion driving, but uses riding wheel for transmission.

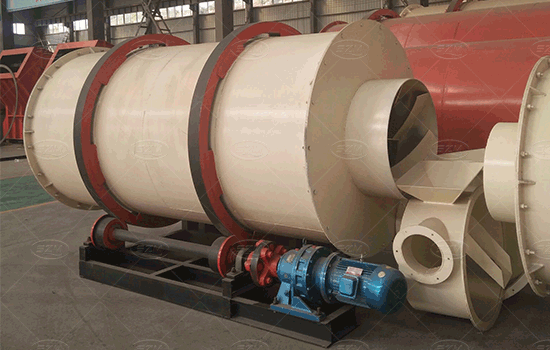

Working principle of Three Drum Dryer

Materials enter the inner side of the drum through the feeding device to realize current flow drying process,then the materials enter the middle layer of the inner wall through the other end to realize counter current drying process.They are lifted in over and over in the middle layer which advance in two-steps forward and one-step back way.The three-drum dryers absorb heat from both inner drum and middle drum,which extend the drying time and realize the best drying condition.Finally,materials fall into the external layer of the drum from the other end of the middle layer, processing in a rectangle multi-loop way.The dried materials move quickly out of the drum under the hot air,while the wet ones remain because of their own weight.Materials are dried completely inside the rectangle shoveling plate and then cooled by the single drum cooler, thus finishing the whole drying process.

Product Data

Technical Data of Three Drum Dryer:

Model

Outer cylinder diameter (m)

Outer cylinder length (m)

Speed (r/min)

Volume (m ³)

Capacity(t/h)

Power (kw)

Ф1.38х1.8

1.38

1.8

3-10

2.6

1-3

3

Ф1.6х2.2

1.6

2.2

3-10

4.4

4-5

5.5

Ф1.8x3.6

1.8

3.6

3-10

9.1

6-8

7.5

Ф2x4

2

4

3-10

12.5

8-12

3*2

Ф2.2х4.5

2.2

4.5

3-10

17

10-15

7.5*2

Ф2.5x6

2.5

6

3-10

31

15-20

5.5*4

Ф2.7x7

2.7

7

3-10

40

20-30

7.5*4

Ф3x7

3

7

3-10

49

30-40

7.5*4

Ф3.2x8

3.2

8

3-10

64

40-50

11*4