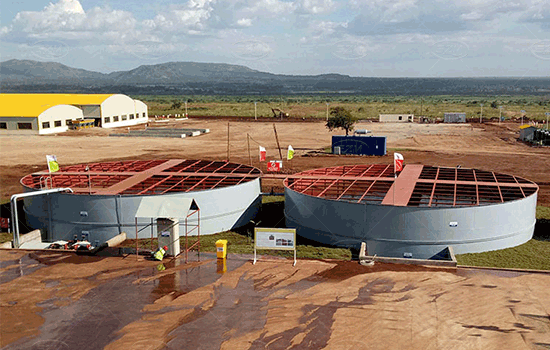

Concentration tank

Concentration tank

Total Weight:1.8–204.6(t)

Charge Amount:1.8-204.6(t)

Processing Ability:5.6–6250(t/d)

Applied Materials:Slime, waste water, waste slag, etc

Features and technology advantages of Concentration tank

Thickening tank, sewage treatment concept, also known as sludge thickening tank. Generally, it adopts the shape of vertical flow or radial flow. It can be divided into intermittent operation and continuous operation. The former is mainly used in small sewage treatment plants or sewage treatment plants of industrial enterprises, while the latter is used in large and medium-sized sewage treatment plants. The form of continuous gravity concentration tank is the same as that of radial flow sedimentation tank. It can be divided into three types: sludge scraper and sludge mixing device, without sludge scraper and multi-layer concentration tank.

Application Fields of concentration tank

High efficiency concentrator is widely used for processing slime, waste water and waste residue in metallurgy, mining, coal, chemical industry, building materials industry, environmental protection and other departments. It can improve the utilization rate of return water and bottom flow concentration, which also has important significance for environmental protection.

Features of concentration tank

1. Strong sludge storage capacity and low power consumption.

2. The concentration speed is fast, the floor area is small, and the mud scraping is convenient.

3. The required hardware is not complex and the cost recovery is faster.

Working principle of Concentration tank

The thickener has continuous and intermittent operation modes. Continuous operation refers to continuous sludge feeding and continuous sludge discharge, which is relatively easy to achieve in large-scale sewage treatment plants. Small sewage treatment plants can only intermittently feed and discharge sludge, because the primary sedimentation tank can only operate intermittently. Continuous operation can keep the sludge layer stable, which is beneficial to the thickening effect. The treatment plant that cannot operate continuously should "frequently enter and discharge" to make the operation as continuous as possible. Of course, this largely depends on the sludge discharge operation of the primary sedimentation tank. When "frequent discharge" is not possible, at least timely sludge discharge shall be ensured, and each time sludge discharge must not be excessive, otherwise the sludge discharge speed will exceed the concentration speed, making the sludge thinner and damaging the sludge layer.

Product Data

Technical Data of concentration tank:

Model

Tank diameter (mm)

Pool depth (mm)

Subsidence(㎡)

Capacity(t/d)

Motor model

Power (kw)

Weight of steel tank(kg)

Total weight(kg)

NZSG-2.5

2500

1850

4.9

5-22.4

Y90L-6

1.1

1000

2225

NZSG-3A

3000

1800

7

5-23.3

Y100L-6

1.5

1664

3168

NZSG-3

3600

1800

10.2

5-28.5

Y100L-6

1.5

2097

3680

NZSG-5

5000

2956

16

16-90

Y90L-4

1.5

5160

7908

NZSG-6

6000

2956

28.3

98

Y90L-4

1.5

5769

8772

NZSG-7

7000

3000

38.5

140

Y112M-6

2.2

8800

13862

NZSG-8

8000

3318

50.2

185

Y132S-6

3

12966

19158

NZSG-9

9000

3376

63

210

Y132S-6

3

15418

21733

NZSG-12

12000

3600

113

370

Y132S-6

3

25589

34823

NZSG-15

15000

3600

176

580

Y132S-4

5.5

35800

54315

NZSG-18

18000

4400

255

960

YCT200-4B

7.5

52485

73588

NZSG-20

20000

4400

315

1400

YCT200-4B

7.5

59365

76312