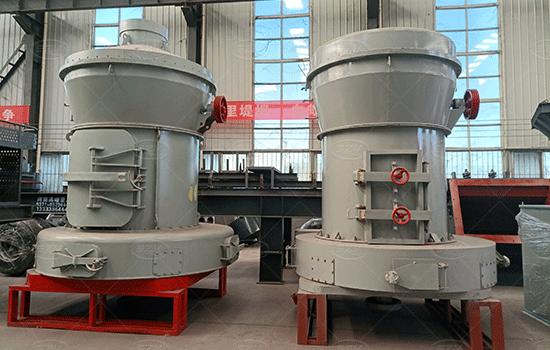

Raymond Mill

Raymond Mill

Feeding Size:≤25(mm)

Discharging Size:0.125-0.044(mm)

Capacity:0.5–60(t/h)

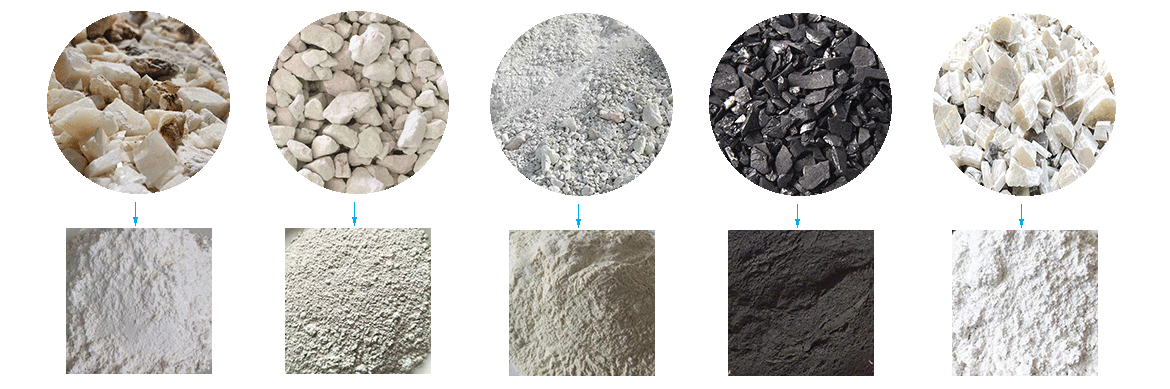

Applied Materials:Barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, gypsum, iron oxide red, slag, grain slag, clinker, insulation materials, etc

Features and technology advantages of Raymond Mill

Raymond mill is suitable for medium and small sized mines, chemical plants, smelting plants, ore dressing plants, pharmaceutical companies, refractory material factory, cement plant and other powder making industry. Raymond mill belongs to high efficiency closed-circuit ultrafine grinding equipment, which can replace ball mill. The air flow of Raymond mill is circulating from fan cyclone separator pipe fan.

It has less exhaust dust and clean operation workshop without pollution to the environment. Raymond mill has high output, wide usage, energy saving, convenient operation, low repair rate and small occupation area, which is the ideal investment equipment for small flour enterprises to obtain higher profits. Raymond mill also has other names for example Raymond pendulum mill, Raymond roller mill and Raymond grinding mill.

Structural Composition of Raymond Mill

The structure of the machine is mainly composed of main machine, analyzer, fan, finished cyclone separator, micro powder cyclone separator and air duct. The main engine is composed of frame, air inlet volute, blade, grinding roller, grinding ring and cover.

1.The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. From crushing of raw material to grinding and packing is an independent production system.

2.Compared with the ball mill, the Raymond mill has higher efficiency, lower power consumption, smaller covered area, less investment.

3.The final products sieve rate can reach 99%.

4. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

5. Main parts of the whole plant are made from cast and steel of high quality. The technique is so subtly that insures the durability of whole plant.

6.Less powder dust, environmental protection and energy saving, easy maintenance.

Working principle of Raymond Mill

After the Raymond mill breaks the bulk raw materials to the required feed size, the materials are transported to the storage bin by the dustpan elevator, and then uniformly sent to the grinding chamber of the main machine by the electromagnetic vibration feeder. The materials entering the grinding chamber are grinded between the grinding roller and the grinding ring. The pulverized powder is carried to the analyzer by the air flow of the fan for classification. The fine powder meeting the fineness requirements flows through the pipeline into the cyclone collector for separation and collection, The finished product is discharged through the discharger. The blade system plays a very important role in the operation of the host machine. It is located at the lower end of the grinding roller. During the same rotation of the blade and the grinding roller, the material is shoveled up and thrown into the roll ring of the grinding roller to form a padding layer. The material layer is crushed by the outward extrusion force generated by the rotation of the grinding roller, thus achieving the purpose of milling.

Product Data

Technical Data of Raymond Mill:

| Model | Number of rolls | Grinding roll size (mm) | Maximum feed size (mm) | Finished material size (mm) | Capacity(t/h) | Motor power (Kw) | Dimension (mm) | |

| Main motor | Small motor | |||||||

| YGM6515 | 3 | 210×150 | 12-20 | 0.025-0.613 | 0.25-2 | 15 | 11 | 4100×3300×4500 |

| YGM7815 | 3 | 260×150 | 15-20 | 0.025-0.613 | 0.28-2 | 18.5 | 15 | 4300×3500×4500 |

| YGM8314 | 3 | 270×150 | 15-20 | 0.025-0.613 | 0.35-3.4 | 22 | 18.5 | 5300×4100×5200 |

| YGM3016 | 3 | 300×150 | 15-20 | 0.025-0.613 | 0.45-5 | 30 | 22 | 5300×4100×5200 |

| YGM9517 | 4 | 310×170 | 15-25 | 0.025-0.613 | 0.8-7 | 37 | 30 | 7100×5900×7900 |

| YGM4121 | 5 | 410×210 | 15-25 | 0.025-0.613 | 1.8-10 | 75 | 75 | 7850×8000×9700 |

| YGM130 | 5 | 410×190 | 15-25 | 0.025-0.613 | 2-11 | 75 | 75 | 7850×8000×9700 |

| YGM160 | 6 | 450x 280 | 15-35 | 0.025-0.613 | 3-18 | 132 | 132 | 12550×5700×8600 |