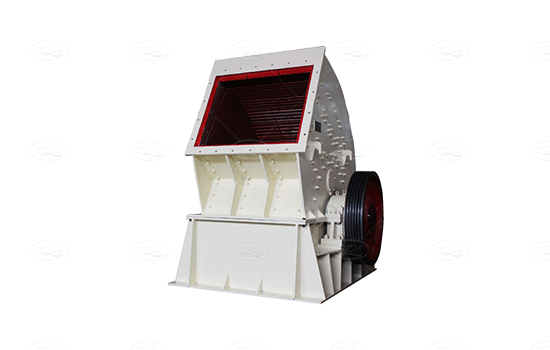

Heavy Hammer Crusher

Heavy Hammer Crusher

Max Feeding Size:1100(mm)

Stone Hardness:≤150(Mpa)

Power:90-600(kw)

Capacity:140-2000(t/h)

Features and technology advantages of Heavy Hammer Crusher

The heavy hammer crusher is one of the crushing equipment. It eliminates the initial crushing process of the jaw crusher and becomes a new model for the one-time crushing of large and small materials. It has large output, high efficiency, low power, saves manpower and material resources, and reduces the crushing cost of materials. The crushed stone of the machine is not only complete in specifications, but also uniform and clear. Suitable for crushing all kinds of medium hardness and brittle materials. Such as limestone, coal and other materials. Mainly used in cement, mining, coal preparation, power generation, chemical and building materials industries.

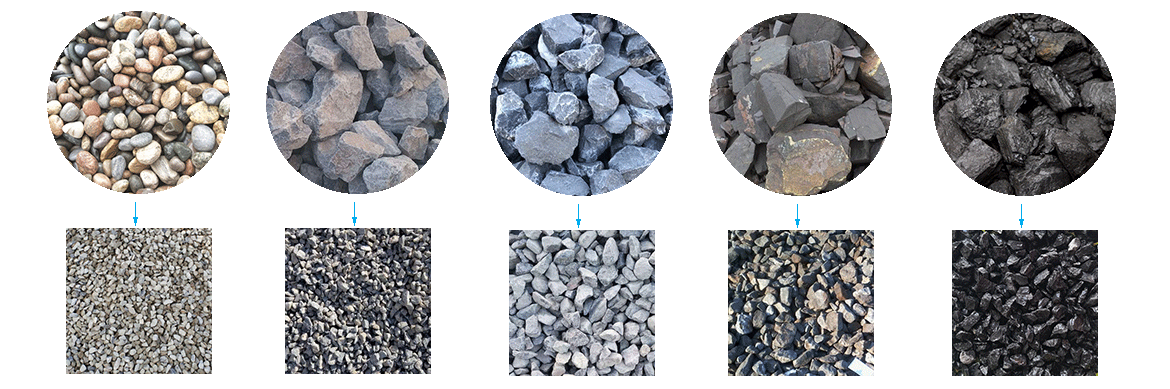

Application of Heavy Hammer Crusher

Heavy hammer crusher is widely used for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The large capacity makes heavy hammer crusher becomes the preferred equipment in large stone crushing industry.

1. The utility model has the advantages of large feeding particle size, large fine crushing ratio and high efficiency;

2. Simple structure, compact assembly and light weight;

3. The particle size of the product is uniform, and the over broken powder is less;

4. Easy maintenance, little wear;

5. It has the advantages of low power consumption and is used as the crushing equipment for medium and fine crushing.

Working principle of Heavy Hammer Crusher

The materials are fed into the machine from the upper feeding port and are crushed by the impact, impact, shearing and grinding of a high-speed hammer. At the lower part of the rotor, there is a sieve plate. Particles smaller than the size of the sieve hole in the crushed materials are discharged through the sieve plate. Coarse particles larger than the size of the sieve hole are retained on the sieve plate and continue to be hit and ground by the hammer. Finally, they are discharged out of the machine through the sieve plate.

Product Data

Technical Data of Heavy Hammer Crusher:

Model

Rotor diameter*length (mm)

Feeding port (length*width) (mm)

Optimal feed size (mm)

capacity (t/h)

Motor power (kw)

Dimensions (L x W x H) (mm)

PCZ1308

1330x790

870x780

≤380

60-160

132

2880x2130x2390

PCZ1410

1400x1000

1060x740

≤450

80-210

2x90(160)

2830x2100x2485

PCZ1610

1600x1000

1090x930

≤480

100-230

2x132

3370x2415x2750

PCZ1612

1600x1200

1340x1140

≤500

120-350

2x160

3370x2613x2750

PCZ1615

1600x1500

1570x1140

≤550

200-550

2x200

3370x2925x2750

PCZ1716

1700x1600

1420x1200

≤600

400-850

2x250

3520x3000x3210

PCZ1720

1700x2000

2030x1200

≤650

500-1000

2x400

3670x3390x3330

PCZ1920

1900x2000

1980x1210

≤750

800-1500

2x500

4490x3910x3600

PCZ2225

2200x2500

2530x1610

≤1000

1500-3000

1250

4890x5010x4560