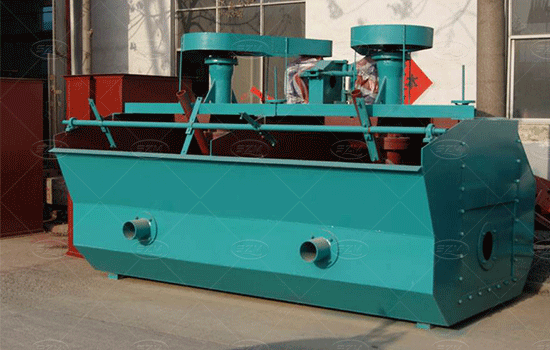

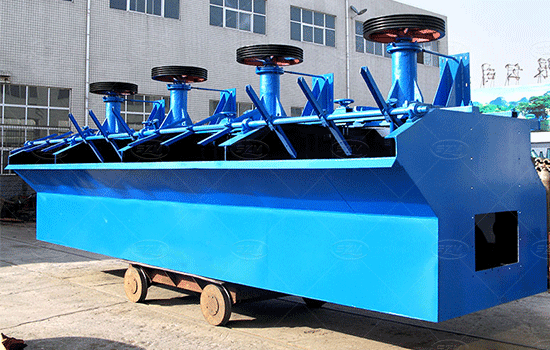

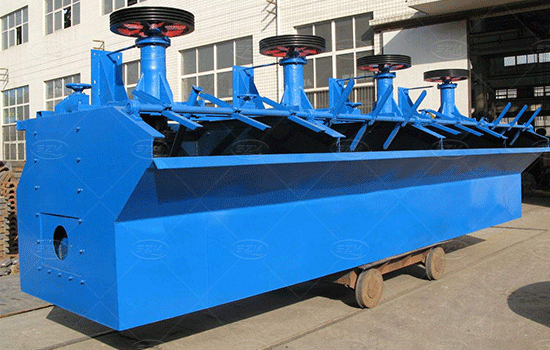

Flotation Machine

Flotation Machine

Capacity:0.2–16(m³/min)

Feeding Size:200(mesh no less than 80%)

Application:Copper sulfide, gold sulfide, zinc, lead, nickel, antimony, fluorite, tungsten, and other non-ferrous metals, and also be used for coarse selection for ferrous metals and nonmetals.

Type:Agitating flotation machine, Self-priming, aeration flotation, flotation column.

Features and technology advantages of Flotation Machine

Flotation machine is the abbreviation of floating concentrator, which refers to the mechanical equipment that completes the flotation process. In the flotation machine, some of the ore particles are selectively fixed on the air bubbles by stirring and aerating the pulp treated by adding chemicals; It floats to the pulp surface and is scraped out to form foam products, while the rest is retained in the pulp to achieve the purpose of separating minerals. There are many structural forms of flotation machines, the most commonly used is mechanical stirring flotation machines. It is mainly used to separate copper, zinc, lead, nickel, gold and other non-ferrous metals, and can also be used for rough selection and selection of ferrous and non-metallic metals.

Application of Flotation Machine

Flotation machine can be used for separating copper, lead-zinc ore, molybdenum ore, graphite ore, fluorite ore, phosphate, selected gold, silver, iron, rare earth ore, talc and so on. It is widely used in the separation and recovery for fine minerals of ferrous metal, precious metal, nonferrous metal, non-metallic minerals, rare metal, non-metal, etc.

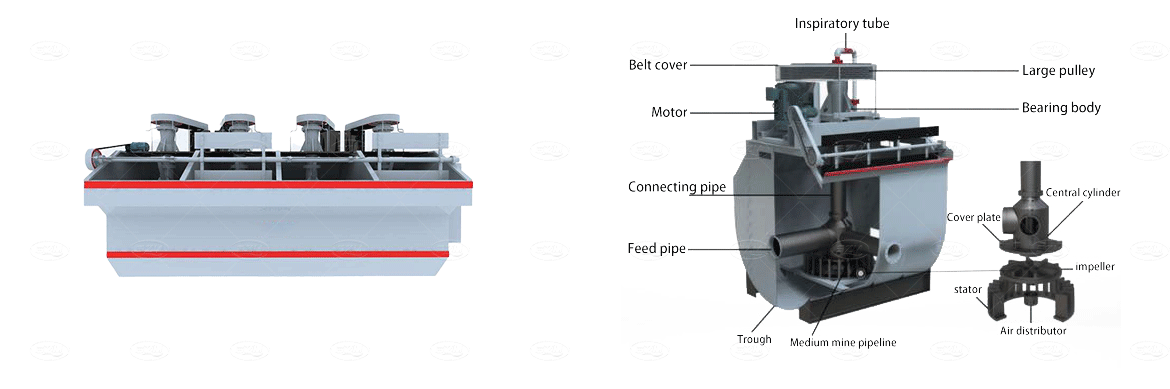

The flotation machine is mainly composed of slurry tank, agitation device, air charging device, discharge mineralized bubble device, motor, etc. our company produces a wide variety of flotation machines, such as mechanical flotation machine, air charging agitation flotation machine, etc.; the models are complete, such as XJK, JJF, SF, BF, kfy, XCF, etc. At present, mechanical agitation flotation machine is commonly used.

Advantages of Flotation Machine

1. Large suction capacity, low power consumption, neat equipment configuration, simple operation and maintenance.

2. Each tank has three functions of suction, slurry suction and flotation, forming a flotation circuit without any auxiliary equipment. It is horizontally configured to facilitate process change.

3. The slurry circulation is reasonable and can reduce coarse sand sedimentation.

4. It is equipped with automatic control and electric control device for pulp surface, which is convenient for adjustment.

Working principle of Flotation Machine

The flotation machine is driven by the motor V-belt to drive the impeller to rotate, generating centrifugal action to form negative pressure. On the one hand, sufficient air is inhaled to mix with the pulp, on the other hand, the pulp is stirred to mix with drugs, and at the same time, the foam is refined, so that the minerals are bonded to the foam and floated to the pulp surface to form a mineralized foam. Adjust the height of the ram and control the liquid level so that the useful foam can be scraped out by the scraper..

Product Data

Technical Data of Flotation Machine:

Type

Model

Effective volume(m³)

Capacity(m³/min)

Principal axis

Scraper

Tank size (length × wide × High)(mm)

Single slot weight(t)

Power(kw)

Speed(r/min)

Speed(r/min)

Power(kw)

XJK floatation machine

XJK-0.35

0.35

0.18-0.4

1.5

483

25

1.1

700×700×700

0.5

XJK-0.62

0.62

0.3-0.9

3

400

25

1.1

900×820×850

1

XJK-1.1

1.1

0.6-1.6

5.5

330

25

1.1

1100×1100×1000

1.4

XJK-2.8

2.8

1.5-3.5

11

280

25

1.1

1750×1600×1100

2.5

XJK-5.8

5.8

5-7

22

240

25

1.5

2200×2200×1200

3.6

SF floatation machine

SF-0.37

0.37

0.2-0.4

1.5

386

25

1.1

700×700×750

0.5

SF-0.7

0.7

0.3-0.9

3

400

25

1.1

900×820×950

1

SF-1.2

1.2

0.6-1.6

5.5

330

25

1.1

1100×1100×1100

1.9

SF-2.8

2.8

1.5-3.5

11

268

25

1.1

1750×1600×1150

2.6

SF-4

4

2-4

15

220

25

1.5

1850×2050×1200

2.9

SF-8

8

4-8

30

191

25

1.5

2200×2900×1400

4.2

SF-10

10

5-10

30

191

25

1.5

2200×2900×1700

4.5

SF-20

20

5-20

30×2

191

25

1.5

2850×3800×2000

9.9

JJF floatation machine

JJF-2

2

1-3

7.5

443

25

1.5

1400×1400×1100

1.7

JJF-4

4

2-4

11

305

25

1.5

1600×2150×1250

2.4

JJF-8

8

4-8

22

233

25

1.5

2200×2900×1400

4.5

JJF-10

10

5-10

22

233

25

1.5

2200×2900×1700

4.9

JJF-16

16

5-16

30

180

25

1.5

2850×3800×1700

8

JJF-20

20

5-20

37

180

25

1.5

2900×3800×2000

10.5