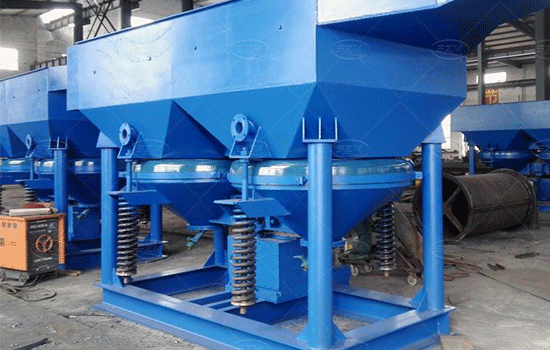

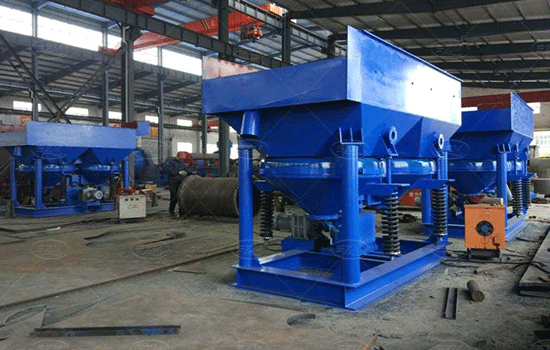

Jigger Machine

Jigger Machine

Material Size:2~18(mm)

Capacity:1-20(t/h)

Type:Wet separation, dry separation

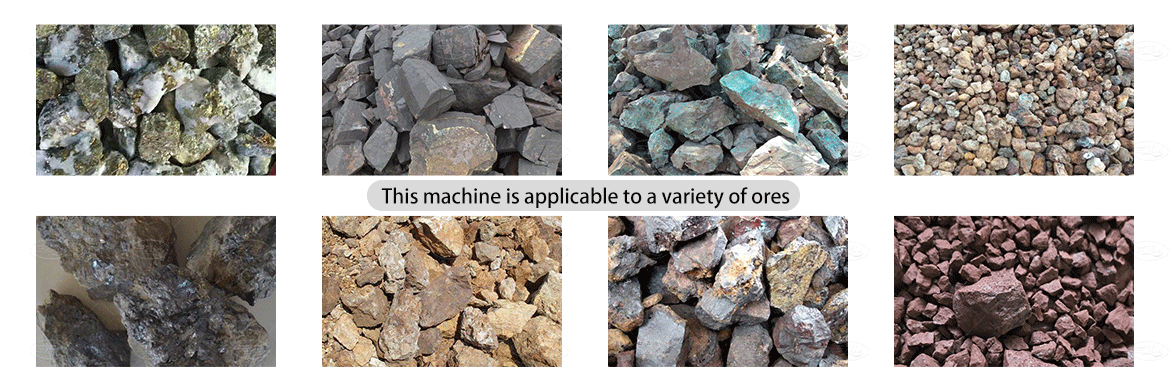

Application:Jigging machine is a gravity separator used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc.

Features and technology advantages of Jigger Machine

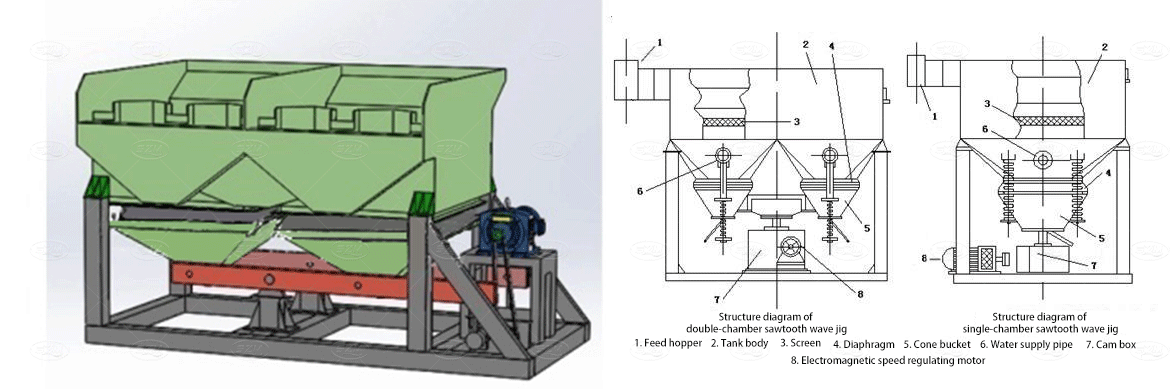

Sawtooth wave jigger belongs to single row double chamber downward moving jig. It uses water as mineral processing medium and carries out separation according to the specific gravity (density) difference between useful minerals and gangue. The sawtooth wave jig has the characteristics of uniform upward flow and rapid downward flow because of its sawtooth waveform of pulsation curve. The waveform of flow fluctuation produced in normal operation is sawtooth waveform, which enhances the suction effect of the sawtooth wave jig in mineral processing, and is very beneficial to the recovery of fine minerals and saves water. And the characteristics of continuous work. Sawtooth wave jig covers a small area and is easy to operate. It is an efficient, energy-saving and environmental-friendly mineral processing equipment developed and produced in recent years. It has a very good effect on the mineral processing of many kinds of metal and non-metallic minerals. It is especially suitable for the mineral processing of fine-grained minerals, the recovery and treatment of metal smelting slag and mine tailings. The processing area has played a very important role.

Applications of Jigger Machine

Jigging machine is one of the relative new methods for gravity concentration. As a rougher or cleaner device, it is widely applied on the separation of diamond, gold, ungsten, iron, tin, hematite, coal, tantalum-niobium, titanium, manganese, barite, zirconium, chrome, gemstone and other minerals due to its high processing capacity, large range of separation size and simplicity of operation and maintenance.

Advantages of Jigger Machine

1.Stroke and jig frequency are easy to adjust

2.The advanced frequency conversion speed control technology is convenient to operate and manage;3.Small cover area, high processing capacity per unit area.

Working principle of Jigger Machine

When the transmission mechanism drives the diaphragm to move back and forth, the water in the jig chamber will pass through the screen and produce a vertical alternating pulsating water flow. The selected materials are fed to the bed and form a particle group system with the bed ore and water. When the water flows upward, the particle group is in loose suspension state. At this time, the ore particles with different weight and size settle at different speeds, and the high-density coarse particles (bed stones) settle in the lower layer. When the water flow drops, it will produce suction, and the ore particles with large density and small size will enter the lower layer through the bed gap.

Product Data

Technical Data of Jigger Machine:

|

Model |

Chamber |

Feeding Size(mm) |

Make-up Water(m3/t) |

Pressure of Water(Mpa) |

Processing Capacity(t/h) |

Motor Power |

Dimension |

Weight |

|

|

Shape |

Area(m2) |

(Kw) |

(mm) |

(kg) |

|||||

|

JT0.57-1 |

Ladder |

0.57 |

<6 |

1-3 |

≥0.5 |

1-2.5 |

1.5 |

1550x780x1530 |

610 |

|

JT1-1 |

Ladder |

1.04 |

<10 |

1-3 |

2-4 |

2.2 |

2270x1110x1890 |

900 |

|

|

JT2-2 |

Rect. |

2.28 |

<10 |

1-3 |

4-8 |

3 |

3225x1550x2050 |

1640 |

|

|

JT3-1 |

Ladder |

3.3 |

<10 |

1-3 |

≥0.5 |

6-10 |

5.5 |

3180x2000x2600 |

3260 |

|

JT5-2 |

Ladder |

4.86 |

<10 |

1-3 |

10-15 |

7.5 |

3600x2000x2600 |

4500 |

|

|

JT1.5-2 |

Rect. |

1.53 |

<30 |

1-2 |

≥0.5 |

5-8 |

3 |

3200x1550x2050 |

1520 |

|

JT4-2 |

Rect. |

4.33 |

<30 |

1-2 |

10-15 |

7.5 |

3600x1850x2600 |

4600 |

|