Rod Mill

Rod Mill

Feeding Size:≤50(mm)

Capacity:0.62-180(t/h)

Applied Materials:Quartz, iron ore, copper ore, gold ore, glass, construction waste, cement clinker, etc

Applicable Range:Rod mill is used to grind materials in the industries like refractory material, chemical industry, metallurgy and glass industry etc. which has a strict requirements for the evenness of final products

Features and technology advantages of Rod Mill

The rod mill has two forms: dry and wet, and users can choose according to their actual conditions. Our factory adopts advanced controllable material import and export technology, combining the actual abrasive materials with appropriate abrasive, the traditional surface contact is changed to line contact, the granularity of the material is even more uniform and the output is higher, and it is widely used in the grinding operation with high uniformity of the wear resistance, chemical industry, metallurgy, glass and other industries. In recent years, it is also used for sand making in building sand.

Applications of Rod Mill

1. Rod mill is suitable for grinding various ores and other materials, which is widely used for grinding operations in refractory industry, chemical industry, metallurgy industry, glass and other industries. The requirements of finished particle size are relatively high. In recent years, it is also used in sand making industry.

2. The gravity or magnetic separation plants of tungsten, tin and other rare metal ores often adopt rod mill in order to prevent the harm caused by over crushing.

Features of Rod Mill

During the grinding process of rod mill, the grinding medium and ore are line contact, thus it has a certain selective grinding effect. The particle size of the product is more uniform with low grinding rate. For coarse grinding, the processing amount of rod mill is greater than the ball mill with the same specification, and vice versa.

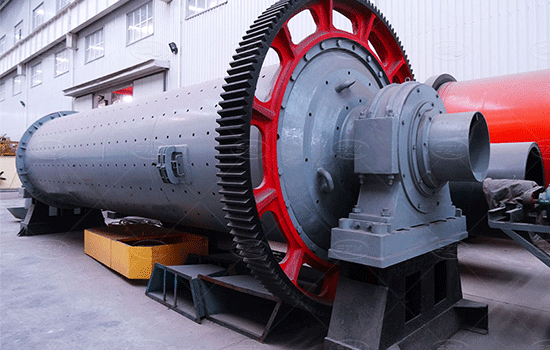

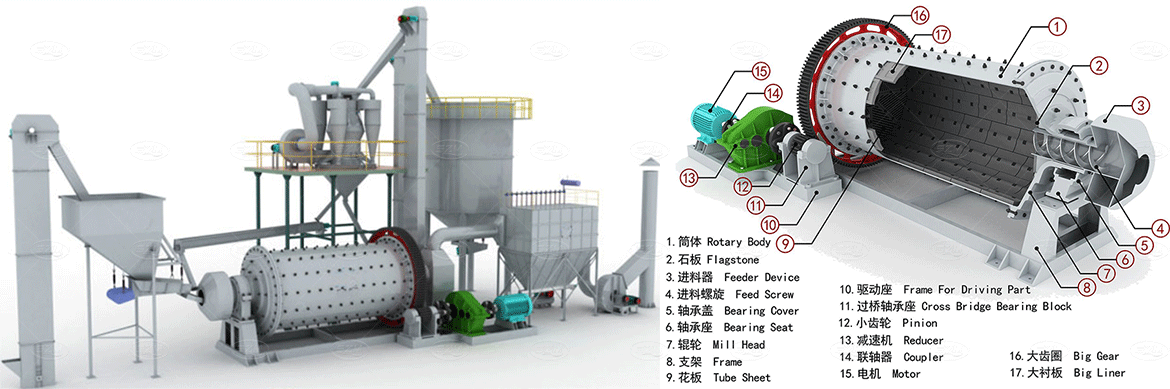

Working principle of Rod Mill

The rod mill is driven by the motor through the reducer and the big gear around it or by the low-speed synchronous motor directly through the big gear around the rod mill to drive the cylinder rotation. The cylinder is equipped with appropriate grinding medium-steel rods. Under the action of centrifugal force and friction , grinding medium is lifted to a certain height and fall. The grinding material continuously entered the cylinder body by the feeding device, crushed by the grinding medium, and discharged from the machine by the overflow and continuous feeding force, so as to carry out the next stage of operation.

Product Data

Technical Data of Rod Mill:

Model

Cylinder diameter (mm)

Cylinder length (mm)

Motor model

Motor power (kw)

Motor speed (r/min)

Dimension (mm)

Capacity(t/h)

Effective volume(m3)

Weight(kg)

MBY 0918

900

1800

Y225M-8

22

730

4980x2370x2020

0.62~3.2

0.9

5700

MBY 0924

900

2400

Y250M-8

30

730

5670x3280x2020

0.81~4.3

1.2

5880

MBY 1224

1200

2400

Y280M-8

45

730

6450x2800x2500

0.4~4.9

2.28

12308

MBY 1530

1500

3000

JR125-8

95

725

7935x3185x2280

5

19990

MBYg 1530

1500

3000

JR117-8

80

725

7253x3070x2280

2.4~7.5

5

21210

MBYg 2130

2100

3000

JR136-8

180

735

8122x4220x3073

14~35

9

42123.5

MBYg 2136

2100

3600

JR137-8

210

735

8958x4320x3025

43~61

10.8

45800.5

MBYg 2430

2400

3000

JR138-8

280

735

9004x4836x3490

11.5

55795

MBYg 2732

2700

3200

JR157-8

320

750

10509x5000x3620

15.7

83110

MBYg 2736

2700

3600

JR158-8

380

743

10764x5750x3620

32~86

17.7

90441

MBY 2740

2700

4000

TDMK400-32

400

187.5

12300x5700x4700

43~110

20.4

75000

MBY 3040

3000

4000

JR1510-8

570

740

9800x3900x3900

54~135

26

90000

MBY 3245

3200

4500

TDMK800-36

800

167

14600x7000x5300

64~180

31

113000

MBY 3645

3600

4500

TDMK1250-40

1250

150

15200x8800x6800

80~230

41.8

139000

MBY 3654

3600

5400

TDMK1600-40

1600

150

15900x8800x6800

100~250

49.7

150000