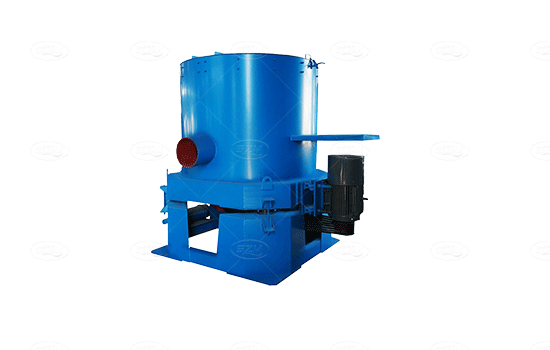

Centrifugal Gold Concentrator

Centrifugal Gold Concentrator

Feeding Size:0-6(mm)

Capacity:0-100(t/h)

Processible Material:Alluvial gold, rock gold after grinding, and other precious metals

Type:Vertical auto discharging centrifuge and vertical type manual discharging centrifuge

Features and technology advantages of Centrifugal Gold Concentrator

Introduction of Centrifugal Gold Concentrator

The centrifugal gold concentrator, also known as water jacket centrifuge, has a wide range of uses, not only in sand gold beneficiation, but also in the recovery of natural gold from rock gold. It can also recover the gold left in the waste ore during normal gold separation. Through continuous research and testing, the gold yield of our centrifugal gold concentrator has reached more than 99%, so it can be used as a gold concentrator, The selection ratio can reach nearly 1000 times, and its highest efficiency can be more reflected in the ore processing operation of vein gold. When the raw material granularity reaches a certain level, the selection ratio of each individual can reach more than 98%, and the recovery rate of some relatively special individuals can reach more than 97%.

Advantages of Centrifugal Gold Concentrator

1. The beneficiation ratio is very high, the concentrate yield is very small, and the gold recovery rate is higher than that of gravity separation equipment such as chutes.

2. The whole sorting process is fully automatic, stable and reliable, with good wear resistance of vulnerable parts and a running rate of about 97%.

3. No chemical agent is added and there is no problem of environmental pollution.

4. Less power consumption, less labor, low production cost, and the return time is generally less than half a year.

5. Large processing capacity, with the maximum processing capacity of 650 tons per hour.

6. It covers a small area and is easy to integrate into the process of the existing concentrator.

Working principle of Centrifugal Gold Concentrator

When the centrifugal gold separation equipment works, the selected slurry is first fed into the ore feeding distributor through the ore feeding pipe, and then flows into the ore feeding tank, and then enters the centrifuge drum through the pipe. The slurry is fed into the inner wall of the small head part of the drum along the rotation direction of the drum. The drum rotates at a speed of 150~500 revolutions per minute. Under the action of centrifugal force and flow film, the heavy minerals are precipitated onto the inner wall of the drum, become concentrate, and rotate with the drum. Light minerals are washed away by the flow film on the surface of the concentrate layer along the slope direction of the drum, become tailings and flow into the receiving trough, and then flow into the tailings trough through the ore discharge separator. After the completion of ore feeding, the control mechanism deflects the feed distributor into the slurry return tank, the drum stops feeding, and then reverses the rotation direction of the drum with high-pressure water to flush the concentrate close to the inner wall and discharge it into the concentrate tank. After the concentrate is washed clean, the flushing valve closes, the feed separator and the discharge separator also automatically return to their original position, and then automatically feed the ore to start another cycle of beneficiation.

Product Data

Technical Data of Centrifugal Gold Concentrator:

| Model | Capacity(t/h) | Feed size (mm) | Feed concentration (%) | Backwash water volume (t/h) | Concentrate output (kg/h) | Power (kw) | Cone speed (r/min) | Water pressure (Mpa) | Dimension (mm) | Weight (kg) |

| STL-20 | 0.2-0.6 | 0-3 | 0-50% | 1.5-2 | 2-3 | 0.75 | 800 | 0.04 | 790x785x790 | 145 |

| STL-30 | 2-3 | 0-4 | 4-6 | 10-20 | 1.5 | 600 | 0.12 | 1180x1140x1250 | 400 | |

| STL-60 | 10-20 | 0-6 | 10-15 | 30-40 | 5.5 | 460 | 0.25 | 1970x1670x1750 | 1300 | |

| STL-80 | 35-45 | 0-6 | 17-25 | 60-70 | 11 | 400 | 0.35 | 2300x1800x2200 | 2000 | |

| STL-100 | 60-120 | 0-6 | 40-60 | 70-80 | 18.5 | 360 | 0.4 | 2500x2000x2400 | 2500 |